أرسل لنا رسالة

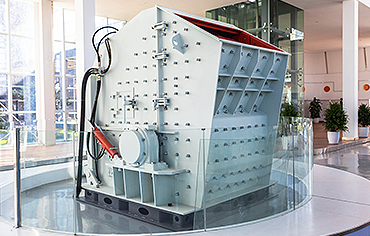

Dry ore dressing equipment

Mining New Value From Your Minerals - ST Equipment

STET’s dry electrostatic separators are ideal for mineral separation—also called ore dressing, beneficiation, or mineral engineering. ... Our dry electrostatic separators beneficiate minerals and metals from relatively coarse, at 600 microns, to very fine, at 1 to 2 micros. ... Our compact

获取价格

MineralsLab – Technological equipment for ore dressing,

Minerals Lab supplies technological equipment for ore dressing, metallurgical, chemical and

获取价格

Iron ore washing process and equipment LZZG

2021/4/14 The gravity separation method does not pollute the environment and has high

获取价格

ZJH minerals – Mining and Mineral Processing Equipment Supplier

Top 10 Best Mineral Processing Equipment Fote Machinery

We Process Most MineralsWe Help You Design The Best Mineral Processing PlantMineral Processing Equipment For SaleFTM Machinery mineral processing equipment can recycle and process various materials: • Metal ores: Gold ore, hematite, magnetite, copper ore, chromium ore, lithium ore, manganese ore, bauxite, galena, tungsten ore, tin ore, nickel ore, molybdenum ore, cobalt ore, etc. • Non-metallic ores: Limestone, dolomite, barite在ftmmachinery上

How to Select And Design Equipment For Ore Dressing Plants?

In the design of ore dressing plants, the selection and design of mineral processing equipment

获取价格

Types of Mining Magnetic Separators - Mineral

6 之 Mining magnetic separator is a common equipment in mineral processing. And magnetic separation is the main method of iron ore dressing. Skip to content. JXSC Machinery. Email Us +86-18879767229 ... to achieve a

获取价格

The role of jigs in modern ore dressing - Sabinet African

Concurrently machines of improved design for dry screening, electrostatic, high tension and magnetic separation and dry gravity concentration became available in the market. The difficulties encountered in dressing jig concentrates in Nigeria and the value of by-product minerals led to the installation of such equipment and stimu

获取价格

MineralsLab – Technological equipment for ore dressing,

Minerals Lab supplies technological equipment for ore dressing, metallurgical, chemical and energy industries, as well as provides maintenance and training services. Minerals Lab helps its customers to find and develop the most effective technological solutions for ore dressing, as well as solutions for the entire cycle from ore to the final ...

获取价格

Chromium Ore Dressing Process Gravity Separation- Henan KaiYun

2024/9/10 Introduction Chromium ore dressing process is mainly a gravity separation process, which is a method of separating minerals according to different mineral densities. The equipment used includes jigs, shaking tables, spiral polarizers, centrifugal concentrators and spiral chutes. Sometimes, the gravity separation concentrate also needs to be re-selected with

获取价格

CN100534626C - Dry tail ore dressing apparatus - Google Patents

The dry tail ore dressing apparatus includes one feeder and features its magnetic dressing units connected serially through connectors and driven with one speed reducing power mechanism. The feeder to feed wind and dressed material into the magnetic dressing units possesses feeding port communicated to the material channels of the magnetic dressing units, and all the

获取价格

Copper Processing Plant, Copper Beneficiation, Equipment - JXSC

Copper ore beneficiation usually adopts gravity separation, flotation, magnetic separation, leaching and other methods. JXSC supports customized copper processing plant and equipment, fully suitable for separating copper oxide ore (azurite, cuprite and malachite); copper sulfide ore (chalcopyrite, bornite and chalcocite) and natural copper.

获取价格

Bentonite Processing Methods And Required Equipment

6 之 Dry beneficiation is generally used to process bentonite with better raw ore quality, or bentonite-rich ore with montmorillonite content of more than 80%.This method is to dry the raw ore in the sun, air dry it naturally or dry it in the oven. It is first crushed manually or with a jaw crusher, and then crushed with a Raymond mill and other roll mills into 100 mesh, 150 mesh,

获取价格

High Intensity Magnetic Separator - JXSC Machinery

High-intensity magnetic separators, or multi-roller magnetic separators, are iron removal/magnetic separation equipment for sorting weak magnetic minerals. It is widely used in limonite, manganese ore, and beach sand mineral processing. This magnetic separator uses a strong magnetic field to effectively dry separate ferromagnetic materials from non-ferrous metal

获取价格

CN1887431A - Dry tail ore dressing apparatus - Google Patents

The dry tail ore dressing apparatus includes one feeder and features its magnetic dressing units connected serially through connectors and driven with one speed reducing power mechanism. The feeder to feed wind and dressed material into the magnetic dressing units possesses feeding port communicated to the material channels of the magnetic dressing units, and all the

获取价格

Mining Magnetic Separation Equipment - JXSC Machinery

Introduction. Capacity: 0.5-180 t/h Wet drum magnetic separator is a widely used magnetic separation equipment for iron, coltan, manganese, tin ore or chrome mineral processing. Separating magnetic ore from 3~0mm fine particle mixture. The drum magnetic separator is mainly used for iron removal and purification in non-metallic mineral sand separation plant,

获取价格

Dressing Equipment - Baichy Heavy Industrial Machinery Co., Ltd.

China Dressing Equipment catalog of Mining Cement Clinker Limestone Powder Rotary Dry Ball Mills Machine Price, Energy-Saving Gold Copper Ore Wet Ball Mill for Sale, Industrial Silica Sand Browncoal Wood Sawdust Rotary Drum Dryer Machine, Three Cylinders Drum Dryer Price provided by China manufacturer - Baichy Heavy Industrial Machinery Co., Ltd., page1.

获取价格

Scheelite Ore Dressing Process and Prospects Mining Pedia

2024/2/27 Drying: The filter cake is then dried using rotary dryers, fluid bed dryers, or other drying equipment to produce a dry concentrate. 6. Concentrate Treatment. The final stage of scheelite ore dressing involves the treatment of the concentrate to remove any remaining impurities and prepare it for smelting.

获取价格

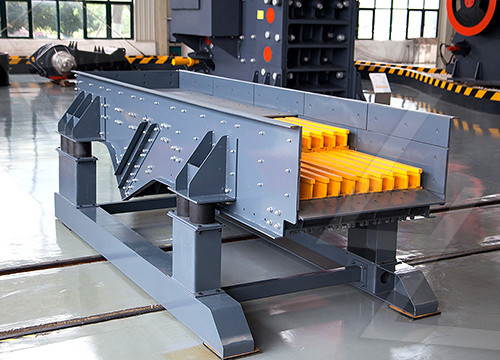

Tailings dry discharge process flowsheet - Jinpeng Mining

In Current years, Tailings dry discharge is a gradual emerging new tailings treatment process. It means the tailing pulp from dressing plant through multi concentration, then use dewatering vibrating screen to treat and get low moisture, easy sediment solidify and good for stockpiling slag. Slag can be transport to fixed position for dry stockpiling.It is a high technological

获取价格

Magnetite Separation Plant, Beneficiation Process, Equipment

1. Single Magnetite beneficiation. Most of the iron minerals in a single magnetite ore are magnetite. The ore composition is simple, and the weak magnetic separation process is often used:. When the grinding particle size is more than 0.2mm, most iron ore magnetic separation plants often adopt a one-stage grinding – magnetic separation process;; When the grinding

获取价格

Dressing Equipment - Baichy Heavy Industrial Machinery Co., Ltd.

China Dressing Equipment catalog of Mining Cement Clinker Limestone Powder Rotary Dry Ball Mills Machine Price, Energy-Saving Gold Copper Ore Wet Ball Mill for Sale, Industrial Silica Sand Browncoal Wood Sawdust Rotary Drum Dryer Machine, Three Cylinders Drum Dryer Price provided by China manufacturer - Baichy Heavy Industrial Machinery Co., Ltd., page1.

获取价格

Scheelite Ore Dressing Process and Prospects Mining Pedia

2024/2/27 Drying: The filter cake is then dried using rotary dryers, fluid bed dryers, or other drying equipment to produce a dry concentrate. 6. Concentrate Treatment. The final stage of scheelite ore dressing involves the treatment of the concentrate to remove any remaining impurities and prepare it for smelting.

获取价格

Tailings dry discharge process flowsheet - Jinpeng

In Current years, Tailings dry discharge is a gradual emerging new tailings treatment process. It means the tailing pulp from dressing plant through multi concentration, then use dewatering vibrating screen to treat and get low

获取价格

Magnetite Separation Plant, Beneficiation Process, Equipment

1. Single Magnetite beneficiation. Most of the iron minerals in a single magnetite ore are magnetite. The ore composition is simple, and the weak magnetic separation process is often used:. When the grinding particle size is more than 0.2mm, most iron ore magnetic separation plants often adopt a one-stage grinding – magnetic separation process;; When the grinding

获取价格

Kaolin Dry And Wet Beneficiation Method - JXSC Machinery

6 之 Advantages of the kaolin dry beneficiation method: Wide range of applications: Dry beneficiation is suitable for kaolin ore with larger particles and can process coarser ore. No need for water source: Dry beneficiation only requires a few water resources, so ore treatment can be effectively carried out in areas where water resources are scarce, reducing the dependence on

获取价格

CN216937115U - Iron ore dressing equipment - Google Patents

The utility model discloses iron ore dressing equipment which comprises a roller mill, a cyclone dust collector, a circulating fan, a first dry magnetic separator and a second dry magnetic separator, wherein the roller mill is provided with a multi-stage particle separator, a ground heavy particle material is discharged from the roller mill, a light particle material enters the multi

获取价格

Iron ore washing process and equipment LZZG

2021/4/14 The gravity separation method does not pollute the environment and has high ore dressing efficiency. The equipment commonly used in iron ore washing plants includes chutes, shakers, jigs, etc., and the chute processing capacity Large, but the recovery rate is low, and the processing capacity of the shaker is low. ... The semi-dry discharge ...

获取价格

Tin Ore Dressing: Gravity, Flotation And Magnetic Separation

2024/7/11 The equipment commonly used in magnetic separation includes dry magnetic separators and wet magnetic separators. Dry magnetic separators are suitable for processing dry or low-humidity tin ore materials, while wet magnetic separators are suitable for processing tin ore materials with high water content. The magnetic field strength and magnetic ...

获取价格

Comprehensive Guide to Copper Ore Processing: Techniques and Equipment

Efficient dressing equipment is another important factor in improving the efficiency of copper ore dressing. Xinhai Mining has been committed to copper ore dressing for more than 20 years and has completed the design and construction of multiple copper ore dressing plants. The following will introduce you to copper ore dressing technology ...

获取价格

Aero Dry Ore Dressing Equipment In Leeds - Dolphin Coast

The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrate (enriched portion) containing most of the ...

获取价格

Tailings - Yantai Jinpeng Mining equipment, ore dressing process ...

In Current years, Tailings dry discharge is a gradual emerging new tailings treatment process. It means the tailing pulp from dressing plant through multi concentration, then use dewatering vibrating screen to treat and get low moisture, easy sediment solidify and good for stockpiling slag. Slag can be transport to fixed position for dry ...

获取价格

Discussion on the Innovation of Copper Ore Dressing Technology

2024/10/28 01 Traditional copper ore dressing methods and existing problems. 1. Gravity separation method. Gravity separation method mainly achieves separation through the difference in specific gravity between copper ore and waste rock. However, the gravity separation method has the problem of low processing capacity and poor recovery effect on fine-grained copper ore.

获取价格

CN1887430A - Dry ore dressing apparatus and its magnetic

The dry ore dressing apparatus with the magnetic separating unit has the oppositely configured like magnetic poles, discharge passage set in the zero-magnetism area between magnetic poles, ring interval around the driving shaft and between the static magnetic yokes and the rotating magnetic yoke, and exciting winding connected to the ...

获取价格

Dry Stack Tailings - ZJH minerals

The equipment lining used in tailings dry discharge process has a wear resistance index up to 128%, and it can be lined with rubber of different characteristics according to the specific properties of slurry, which is widely applicable. ... ZJH mainly focus on producing and supply laboratory and pilot scale type of ore dressing equipment for ...

获取价格