أرسل لنا رسالة

impact of ipcc in grinding mill

CHAPTER 4 METAL INDUSTRY EMISSIONS - IGES

2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inv entories 4.1 .

获取价格

Chapter 11: Industry - IPCC

Metrics Methodology - IPCC

ernmental Panel on Climate Change (IPCC) Fifth Assessment Report (WGIII AR5). The

获取价格

A review on the impact of mining and mineral processing

2019/9/10 The use of grinding media was the largest contributor to environmental

获取价格

Global site-specific health impacts of fossil energy, steel mills, oil ...

2023/8/22 Intergovernmental Panel on Climate Change (IPCC). 2006 IPCC guidelines

获取价格

Assessing the environmental impact of an integrated steel mill

2019/2/20 Carbon dioxide concentrations in the atmosphere have increased rapidly over

获取价格

IPCC - Intergovernmental Panel on Climate Change

3.5 Manufacturing Industry 3.5.1 Introduction. This section deals with greenhouse gas

获取价格

TSD Cement 1-28-09 - U.S. Environmental Protection Agency

2009/1/28 portland cement that needs to be produced, is then ground together in a fine

获取价格

An environmental impact analysis of grinding

In total, 63 *10¹⁵ joules of energy are consumed per year by grinding in manufacturing, 57% of

获取价格

CHAPTER 4 METAL INDUSTRY EMISSIONS - IGES

2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inv entories 4.1 . CHAPTER 4 METAL INDUSTRY EMISSIONS . Volume 3: Industrial Processes and Product Use . 4.2 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories .

获取价格

The impacts of dry stirred milling application on quality and ...

2020/8/15 Furthermore, the use of advanced roller mills, Waste gas from rotary kiln and Up-gradation of mill for finish grinding can save a maximum of 11.9 kWh/t, 17.84 kWh/t, and 25.93 kWh/t electrical energy, respectively. ... Effects of grinding aids on model parameters of a cement ball mill and an air classifier. Powder Technology, Volume 344, 2019 ...

获取价格

Understanding the impact of geotechnical ore properties and blast ...

2021/8/15 Mackenzie (1967) carried out one of the earliest studies in the impact of blasting on downstream mining and mineral processing stages, concluding that adequate rock fragmentation improves the productivity of later steps, such as loading, haulage, crushing and grinding. McKee et al. (1995) conducted the earliest research at JKMRC regarding the

获取价格

机械磨 Condux - 耐驰研磨分散

机械磨 Condux ® 是用于莫氏硬度高达3-3.5的各种干粉精细研磨的干法研磨,取决于应用对象及应用条件。. 机械磨Condux ® 配置有多种研磨工具和腔体设计,可广泛地用于各种干粉的研磨,并可依据特定应用要求,为客户提供定制化设计。. 取决于产品和应用,该磨机可配备不同的转子和定子,

获取价格

The Carbon Impacts of Wood Products - US Forest Service

assumption (Garten 2002, Nave et al. 2010). As for mill residues, the mill residues are a coproduct of the log brought to the production facility. Because mill residues are generated on-site, their use for energy or other purposes such as feedstock for other products is practically 100 percent. Mill residues not used for energy are not considered

获取价格

3.1 CO2 Cement Production - IGES

The Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories (IPCC Guidelines) provide a general approach to estimate CO2 emissions from clinker production, in which the amount of clinker produced is multiplied by the clinker emission factor. The IPCC Guidelines recommend two possible methods for calculating the clinker emission ...

获取价格

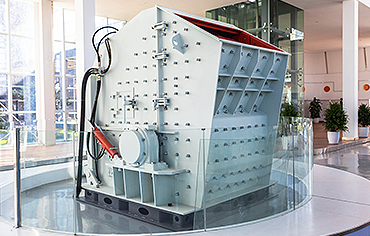

Fine Impact Mills - Hosokawa Alpine

The fine impact mills belonging to the Ultraplex® UPZ product line are used for grinding finenesses in the range 50 µm to 5 mm. A wide range of grinding elements is available, making it possible to operate the UPZ as a pin mill if required.

获取价格

Impact Mill Journal of Surface Investigation: X-ray ... - Springer

2024/7/15 Abstract An impact mill has been developed to produce powders from shavings of refractory metals using the impact grinding method for reuse in electrometallurgy in devices with screw feed, for example, in 3D printers. The proposed device provides high uniformity of grinding with a minimum content of dust fraction and impurity content at low technical and

获取价格

Correlation of grinding rate of gibbsite with impact energy in tumbling ...

2001/10/1 Dry grinding of a gibbsite powder was conducted in air using a tumbling ball mill with mono-size of media (balls) ranging from 4.8 to 31.7 mm diameter to investigate ball size effect on grinding rate. The impact energy of balls during grinding was calculated by the method proposed previously in order to correlate with the grinding rate.

获取价格

Effect of impact on the grinding media and mill liner in a large ...

1987/2/2 The increased height of fall of such grinding balls in these larger mills results in severe impact be- tween the grinding balls and also between the grinding balls and the mill liners. The effect of this impact on the mill liner and the 127 mm diameter grinding balls used in a 8.2 m diameter semiautogenous mill were studied.

获取价格

Ultra-fine grinding and mechanical activation of mine waste

2017/1/10 Further research evaluating the performance of scalable grinding mills is essential in order to continue to develop the technology to the point that its implementation could be viable on an industrial scale. ... IPCC, 2014. IPCC. Climate Change 2014: Synthesis Report. ... Effects of Grinding Variables on Structural Changes and Energy Conversion ...

获取价格

The Evolution and Importance of Grinding Mills in Modern Industry

2023/3/14 Waste Reduction: Grinding mills can help convert waste materials into valuable resources, reducing the environmental impact of industrial processes. Energy Efficiency: Advances in grinding mill technology have led to the development of energy-efficient machines that can perform the same tasks with lower energy consumption, minimizing costs and ...

获取价格

Assessing the environmental impact of an integrated steel mill

2019/2/20 Carbon dioxide concentrations in the atmosphere have increased rapidly over the past decades (approx. 2 ppm/year) exceeding 400 ppm in 2016 (Kahn, 2016).Globally, the industrial sector accounts for about 30% of the CO 2 emissions and one-third of the world energy demand, with the leading industries being: iron and steel, cement, chemicals and petroleum

获取价格

Effects of impact and attrition mechanisms on size distribution

2021/10/1 It was also revealed that the stirred mill and ball mill had varied effects on the minerals (Fig. 21). For all of the minerals, stirred milling was found to be producing more liberated particles than the ball milling and the difference between them became almost disappear through the fine grinding (from p 80 of 330 µm to 38 µm).

获取价格

Ultra-fine grinding and mechanical activation of mine waste

2017/1/10 Further research evaluating the performance of scalable grinding mills is essential in order to continue to develop the technology to the point that its implementation could be viable on an industrial scale. ... IPCC, 2014. IPCC. Climate Change 2014: Synthesis Report. ... Effects of Grinding Variables on Structural Changes and Energy Conversion ...

获取价格

The Evolution and Importance of Grinding Mills in

2023/3/14 Waste Reduction: Grinding mills can help convert waste materials into valuable resources, reducing the environmental impact of industrial processes. Energy Efficiency: Advances in grinding mill technology have led

获取价格

Assessing the environmental impact of an integrated steel mill

2019/2/20 Carbon dioxide concentrations in the atmosphere have increased rapidly over the past decades (approx. 2 ppm/year) exceeding 400 ppm in 2016 (Kahn, 2016).Globally, the industrial sector accounts for about 30% of the CO 2 emissions and one-third of the world energy demand, with the leading industries being: iron and steel, cement, chemicals and petroleum

获取价格

Effects of impact and attrition mechanisms on size distribution

2021/10/1 It was also revealed that the stirred mill and ball mill had varied effects on the minerals (Fig. 21). For all of the minerals, stirred milling was found to be producing more liberated particles than the ball milling and the difference between them became almost disappear through the fine grinding (from p 80 of 330 µm to 38 µm).

获取价格

The impact of different stirrer designs and mill orientations on the ...

2024/4/1 The primary objective of this research is to examine the impact of various stirrer designs in different mill orientations on the efficiency of calcite grinding in a dry stirred mill. In the context of the research, a series of batch grinding experiments were performed using a laboratory-scale stirred mill that could be oriented vertically or horizontally.

获取价格

Ultraplex UPZ Fine Impact Mill - Hosokawa Micron Ltd

The high-performance Hosokawa Ultraplex UPZ fine impact mill is an impressively versatile tailor-made option for the comminution of a wide range of materials into medium to ultra-fine powder between 5mm and 50µm, capable of processing a huge range of raw material up to 3.5 Mohs hardness and for the size reduction of challenging materials, including notoriously tricky cork

获取价格

From single particle impact behaviour to modelling of impact mills

2005/9/1 An approach to simulate grinding in two impact mills based on a population balance model is presented. Different approaches to simulate grinding in different mills are known. For a detailed review of the models refer to Vogel and Peukert (2002). A simple model to describe the single process steps inside the mill (i.e., grinding, classification ...

获取价格

Jet mill grinding of portland cement, limestone, and fly ash: Impact

2013/11/1 A Micron-Master Jet Pulverizer jet mill (0.61 m in diameter)was used in this study to grind the materials as shown in Fig. 1 a and b. The materials to be ground were blended for 60 min in a 0.19 m 2 V-blender (this step is only conducted for blends). After blending, approximately 45 kg of the pre-blended material was transferred into the hopper for jet mill

获取价格

Role of screen plate design in the performance of a rotor impact mill ...

2018/10/15 The role of rotor impact mill screen plate design in biomass grinding has attracted limited interest. This study aimed to clarify the effect of operational parameters and various screen designs on the fine grinding of Sphagnum moss.Contoured screens having forward (rasp) and backward (inverse rasp) inclined trapezoidal apertures of nominal sizes 0.2,

获取价格

Impact of planetary ball mills on corn stover characteristics and ...

2017/10/1 The impact of planetary mill pretreatment on corn stover size, crystallinity, and enzyme digestibility was investigated based on the grinding ball properties in an effort to reduce energy consumption. ... Attrition mills rotate the stirrer to lead the movement of the grinding balls. Conventional ball mills are usually used in conjunction with ...

获取价格

Impact of the powder flow behavior on continuous fine grinding

2018/11/1 1. Introduction. The energy efficiency of dry fine grinding processes can mainly be increased by either (1) further development of mills and mill equipment, (2) improving classifiers as well as grinding-classifying-circuits or (3) enhancing the process behavior of the ground material (Scheibe et al., 1978).Since the demand on fine and ultra-fine materials is still

获取价格

TECHNICAL SUPPORT DOCUMENT FOR THE PULP AND

thermal oxidizers) in 2005 (NCASI 2006). All of these 425 mills fall under NAICS code 3221. The production of paper or paperboard can be divided into three main process areas, which may or may not be co-located at the same facility: (1) pulp production; (2) pulp processing and chemical recovery (at chemical pulp mills); and (3) product forming.

获取价格

Full article: Impact of grinding balls on the size reduction of ...

2024/4/8 Impact of grinding balls on the size reduction of Aprepitant in wet ball milling procedure. Dourna Memarvar a Drug Applied ... and 30 mm. The total time of milling was 210 min in all tests. In each run, the planetary ball mill rotated for 3 min and stopped for 15 min to cool down. After each milling run, the direction of rotation was reversed. ...

获取价格

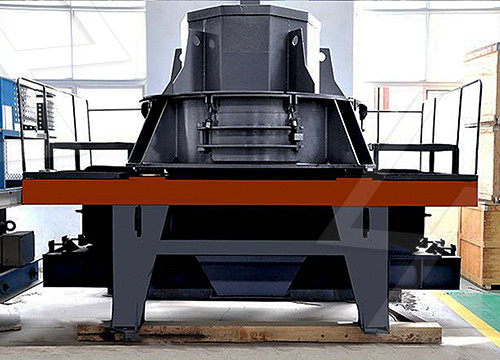

CSM Classifier Mill - NETZSCH Grinding Dispersing

The NETZSCH CSM classifier mill combines a mechanical impact mill with an integrated dynamic air classifier. Grinding Dispersing. About Us. Business Unit Grinding Dispersing of the NETZSCH Group ... Protein Shifting and Enrichment with the use of Dry Grinding and Classifying. Event. 17.01.2025 – 20.01.2025 Conference. Scottsdale, AZ, USA ...

获取价格