أرسل لنا رسالة

dry process rotary kiln cement plant

Manufacturing - the cement kiln - Understanding Cement

Wet Process KilnsDry Process KilnsThe Clinker CoolerGet A Better Understanding of CementThe original rotary cement kilns were called 'wet process' kilns. In their basic form they were relatively simple compared with modern developments. The raw meal was supplied at ambient temperature in the form of a slurry. A wet process kiln may be up to 200m long and 6m in diameter. It has to be long because a lot of water h在understanding-cement上

Cement Rotary Kiln for Dry Process Cement Plant

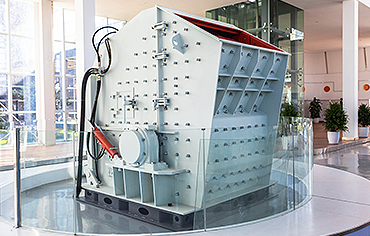

Cement Rotary Kiln Description: Rotary kiln can be divided into Cement Kiln, Metallurgical Chemical Kiln, Lime Kiln, Ceramsite Kiln, Zinc Oxide Kiln, etc.The cement rotary kiln is mainly used for calcining cement clinker, dry process to

获取价格

Key Factors in Rotary Kiln Shell Design - AGICO

Rotary kiln is indispensable core equipment in modern dry process cement plants.The design process of a rotary kiln covers the calculation and formulation of various parameters, which is a very complex process. Here we only briefly

获取价格

Cement Kiln - Cement Rotary Kiln AGICO Cement

Types Of Cement Kilns. When we build a cement plant, there are many types of cement kilns for us to choose from. ... In present cement plants, the new dry process cement rotary kiln is the most widely used. Advantages. Steady

获取价格

Manufacturing - the cement kiln - Understanding

Wet process kilns. The original rotary cement kilns were called 'wet process' kilns. In their basic form they were relatively simple compared with modern developments. ... This reduces the capital costs of a new cement plant. A dry

获取价格

5000tpd Dry Process Cement Plant Project In Liaoning

2020/11/25 Cement equipment list. This is a dry process cement plant customized by a client from Shenyang, Liaoning province. To meet the cement production requirement, the cement production line is equipped with raw mill, cement mill, cement dryer, cement rotary kiln, MBS rod mill, cement packing machine, belt conveyor and other related cement equipment.

获取价格

Rotary Kiln Dryer, Cement Dryer Cement Rotary Dryer - Cement Plant

The rotary kiln dryer, also called cement dryer, is one kind of rotary dryer. rotary kiln dryer apply for drying cement. The cement dryer is made of rotary body, lifting board, transmission, support device, seal ring and etc. The rotary kiln dryer can be

获取价格

Cement Manufacturing Process AGICO CEMENT - Cement Plant

2020/8/25 500tph Limestone Crushing Plant Project In Anhui; 600tpd Rotary Kiln Project In Shandong; 2500tpd Cement Plant Project In Kyrgyzstan; 800tpd Zinc Oxide Rotary Kiln Project In Shandong;.. ... The semi-dry process of cement also belongs to the dry process of cement, add certain water into raw meal powder to make raw meal ball, which ...

获取价格

Dry Process Of Cement Production 300-5000TPD AGICO CEMENT

The dry process cement production line is widely used in cement industry. it is generally divided into the following processes: pre-homogenization of raw materials, homogenization of raw materials, clinker firing, cement grinding, and so on. ... 500tph Limestone Crushing Plant Project In Anhui; 600tpd Rotary Kiln Project In Shandong; 2500tpd ...

获取价格

Comprehensive Guide to Cement Kilns: Processes, Types,

Types of Cement Kilns: Overview of wet, dry, semi-dry, and semi-wet process kilns. Components of a Cement Kiln : Detailed examination of the rotary kiln, preheater, precalciner, and cooler. Kiln Operation and Optimization : Key operational parameters, energy efficiency techniques, and emission control measures.

获取价格

Why Choose Rotary Kiln In Cement Manufacturing Plant? - Cement Plant

Wet-process rotary kiln. The wet process refers that make raw materials into cement slurry contain 32%-40% water. The finished cement slurry is diffluent, so the raw materials have a good mixture, the raw material composition is uniform, so the clinker is high-quality. Dry-process rotary kiln. The dry-process rotary kiln has opposite features.

获取价格

Cement kiln - Wikipedia

The following descriptions of emissions refer to modern kiln plants based on dry process technology. Carbon dioxide During ... While particulate emissions of up to 3,000 mg/m 3 were measured leaving the stack of cement rotary kiln plants as recently as in the 1960s, legal limits are typically 30 mg/m 3 today, and much lower levels are ...

获取价格

Portland Cement Plant for Sale New Dry Process of Portland Cement ...

Using new dry process of Portland cement manufacture, AGICO cement plant achieves high output capacities. ... Rotary Cement Kiln; Indirect Rotary Kiln; LFP Rotary Kiln; Vertical Shaft Kiln; ... The cement manufacturing process in the plant can be divided into seven steps: Step 1 – Raw Material Crushing Pre Homogenization:

获取价格

Kiln For Cement Cement Kiln Rotary Kiln, Shaft Kiln - Cement Plant

The cement rotary kiln has many classifications, in general, there are dry process and wet process according to the raw meal manufacturing process, so the related rotary kiln needed in the cement production can be divided into dry process rotary kiln and wet process rotary kiln. Cement rotary kiln can also be classified by different heat ...

获取价格

How Is Cement Produced in Cement Plants Cement Making Process

The cyclone preheating system Phase IV: Calcination. The calcination is the core phase of the cement making dry process. The calcination of the preheated raw meal takes place in the rotary kiln of the cement plant. The rotary kiln is a huge rotating furnace in which the raw meal is heated up to 1450 ⁰C and turned to clinker.

获取价格

Types of Rotary Kilns - INFINITY FOR CEMENT EQUIPMENT

Such a kiln usually requires additional labor to attend the granulator plant. DRY-PROCESS KILNS. As the term indicates, in this process the kiln feed enters the kiln in dry powder form. Dry-process kiln dimensions are similar to wet kilns in that they are long and typically show a length-to-diameter ratio of approxi mately 30:1 to 35:1.

获取价格

Portland Cement Plant for Sale New Dry Process of

Using new dry process of Portland cement manufacture, AGICO cement plant achieves high output capacities. ... Rotary Cement Kiln; Indirect Rotary Kiln; LFP Rotary Kiln; Vertical Shaft Kiln; ... The cement manufacturing process in the

获取价格

Kiln For Cement Cement Kiln Rotary Kiln, Shaft Kiln - Cement Plant

The cement rotary kiln has many classifications, in general, there are dry process and wet process according to the raw meal manufacturing process, so the related rotary kiln needed in the cement production can be divided into dry process rotary kiln and wet process rotary kiln. Cement rotary kiln can also be classified by different heat ...

获取价格

How Is Cement Produced in Cement Plants Cement

The cyclone preheating system Phase IV: Calcination. The calcination is the core phase of the cement making dry process. The calcination of the preheated raw meal takes place in the rotary kiln of the cement plant. The rotary kiln is a

获取价格

Types of Rotary Kilns - INFINITY FOR CEMENT EQUIPMENT

Such a kiln usually requires additional labor to attend the granulator plant. DRY-PROCESS KILNS. As the term indicates, in this process the kiln feed enters the kiln in dry powder form. Dry-process kiln dimensions are similar to wet kilns in that they are long and typically show a length-to-diameter ratio of approxi mately 30:1 to 35:1.

获取价格

Rotary Kiln Dryer - Cement Dryer AGICO Cement Rotary Dryer

Therefore, the drying process is an essential link in cement production, and the cement dryer is also important cement equipment. Rotary Kiln Dryer Types Direct Heating Type: this type of dryer is permissible for hot gas to direct contact with raw

获取价格

Why Choose Dry Process From Manufacturing Cement Methods

Dry process cement kiln is a kind of rotary kiln which is mainly used in calcining cement clinker. The cement clinker made by the dry process has better quality and stability. It can bring more economical and social benefits in production. ... Rotary Kiln for Cement Plant. Cement Kiln. Activated Carbon Plant. Carbon Carbonization Plant. Carbon ...

获取价格

6 Cement Equipment For Dry-process Cement Production Line

2023/12/26 As we all know, the dry-process cement production line is commonly used in the cement industry. The new type of dry-process cement production process includes four main sections: Pre-homogenization of raw materials, homogenization of raw materials, clinker firing, cement grinding, etc. Raw material conveying system. The raw material, including limestone,

获取价格

Cement Plant Manufacturer Cement Equipment Manufacturers

500tph Limestone Crushing Plant Project In Anhui; 600tpd Rotary Kiln Project In Shandong; 2500tpd Cement Plant Project In Kyrgyzstan; 800tpd Zinc Oxide Rotary Kiln Project In Shandong ... quickly reach to production target”, we have already finished several newly-dry process cement production lines which won great attention and entrust in the ...

获取价格

Cement Bagging Machine Cement Bagging Plant Customization

In addition to cement plants, cement bagging machines can also be used to package other powdered materials similar to cement, such as fly ash, lime powder and mineral powder. cement packing process Cement bagging machines generally use automatic weighing systems, through the controller and sensor to measure and adjust the packaging weight.

获取价格

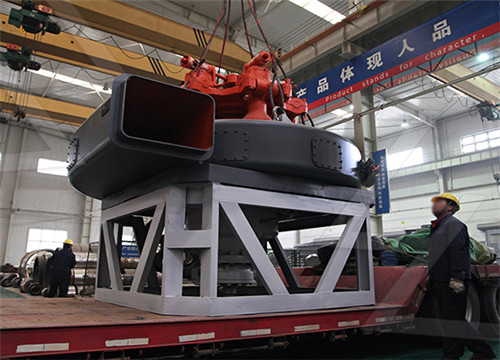

Rotary Cement Kiln Manufacturer - AGICO Cement Plant

The rotary cement kiln we supply is the most ideal cement kiln for the new dry process of cement manufacturing. It has perfect performance on clinker production of ordinary portland cement, white cement, portland pozzolana cement, and so on. AGICO Rotary Cement Kiln Advantages. Over decades, our company has been summarizing experience ...

获取价格

Cyclone Preheater - Cement Plant

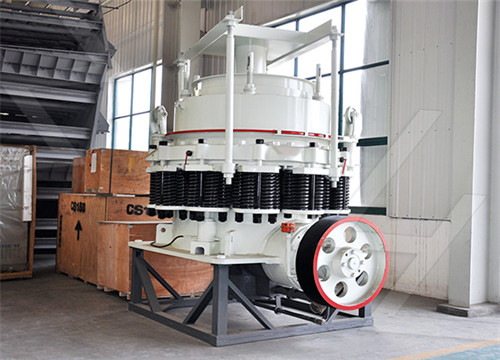

The cyclone preheater, also called cement preheater, suspension preheater, is a kind of preheater in cement plant.As the core equipment of dry method cement production line, cyclone preheater use suspension preheating to preheat and partly decompose the cement raw mix, shorten the length of the rotary kiln, fully mix raw mix and hot air in the kiln, increase heat exchange rate,

获取价格

Leading Supplier of Cement Plant Equipments - Rotary Kiln

At present, it has completed over 60 new dry-process cement clinker production lines of various sizes (300-8000 tons/d), more than 10 pure low temperature waste heat power generation projects for cement clinker production lines and over

获取价格

Cement Rotary Kiln For Sale Rotary Kiln Manufacturer - Cement Plant

Performance: advanced pre-heating system of the dry-process cement rotary kiln increase the kiln speed and the output per unit volume, make sure the high clinker quality.; Fuel: wider choice of fuel, include solid fuel, gaseous fuel, liquid fuel, etc.; Cost: the good sealing effect of the system can fully recycle the waste heat.Less area required also save investment.

获取价格

Cement Kilns: Early rotary kilns

With the arrival of rotary kilns, cement manufacturing processes became sharply defined as wet process or dry process. In the Wet Process, the kiln system is fed with a rawmix in the form of a liquid slurry, typically containing 30-50% of water by mass. In the Dry Process, the kiln system is fed with a rawmix in the form of a dry powder.

获取价格