أرسل لنا رسالة

production process of cement

Cement - Extraction, Processing, Manufacturing Britannica

OverviewExtraction and processingManufacture of cementCrushing and grindingBlendingBurningGrindingRaw materials employed in the manufacture of cement are extracted by quarrying in the case oThe excavated materials are transported to the crushing plant by trucks, railway freight cars, conveyor belts, or ropeways. They also can be transported in a wet state or slurry by pipeline. In regions where limestones of sufficiently high lime content are not available, some process of be在britannica上

How Cement is Made - Cement Manufacturing Process

5

Step-by-Step Guide to the Manufacturing of Cement

Determine the scale of production and type of cement to be produced. Choose an optimal location for the cement plant. Design the layout of the cement factory. Acquire the necessary equipment. Construct the factory and install the

获取价格

Manufacture of Cement- Materials and

Manufacturing of cement involves various raw materials and processes. Each process is explained chemical reactions for manufacture of Portland Cement. Cement is a greenish grey colored powder, made of calcined mixtures of clay

获取价格

Cement: History, Types, Manufacturing Process

2023/8/15 Cement plays a pivotal role in the development and maintenance of urban infrastructure. The substance in question finds application in the production of concrete and mortar, serving the purpose of fortifying the

获取价格

Cement Production: How Cement Is Manufactured CEMEX UK

10. Cement packaging and shipping. The cement is then housed in storage silos, from where it is hydraulically or mechanically extracted and transported to facilities where it will be packaged in sacks or supplied in bulk. In either case, it can be shipped by rail car, freighter truck or ship.

获取价格

The Cement Plant Operations Handbook - International

The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide. Providing a comprehensive guide to the entire cement production process from raw material

获取价格

How Is Cement Produced in Cement Plants Cement Making Process

The cyclone preheater is one of the core equipment for dry process cement production, which consists of a series of vertical cyclones locate on several stages. Inside the cyclones, raw meal meats with the exhaust gas emitting from the rotary kiln and performs suspension heat exchange with it. The suspension pre-heating process helps cement ...

获取价格

Cement Production Demystified: Step-by-Step Process and

Optimizing the production process of cement is also key for our future as the process is very energy intensive and generates a large part of the CO2 emissions worldwide. This article is focusing on the manufacturing process of cement, its carbon footprint, and gives an overview of the production process step by step, other articles on the ...

获取价格

Production Process - Lucky Cement

2019/10/31 Registered Office. Main Indus Highway, Pezu, Distt. Lakki Marwat, Khyber Pakhtunkhawa +92-969-580123-5. Corporate Office . 6-A Muhammad Ali Housing Society, A. Aziz Hashim Tabba Street, Karachi-75350, Pakistan.

获取价格

How cement is made - Heidelberg Materials

All over the world, cement is one of the most important building materials. Whether for houses, bridges or tunnels, we cannot imagine our modern world without it. Join us for a short tour to experience how cement is made: starting with the extraction of raw materials and ending with the finished product.

获取价格

A practical guide to improving cement manufacturing

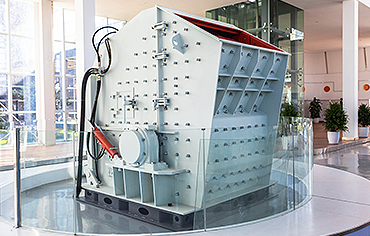

The cement production process 1. The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry. 2. Crusher and Pre-Blending: The material is then crushed to reduce particle sizes and blended to reduce variability in composition. 3. Raw Mill and Kiln: Raw materials and additives are

获取价格

How Is Cement Made? Step-by-Step Guide - BigRentz

2023/12/7 After passing quality control, this mixture, now called raw meal, is ready to move on to the next step in the cement production process. Step 3: Producing Clinker. Trucks transport the raw meal to a production facility where it’s heated in a kiln. Temperatures can exceed 2,642° Fahrenheit (1,450° Celsius) — hotter than most lava.

获取价格

ShapedByConcrete – How Cement is Made

Once crushed, the raw materials are then sent to a laboratory and analyzed – each step of the cement production process is carefully monitored to ensure efficiency and quality. Mixing, grinding, and blending the ingredients ... During this process, cement manufacturers have been a leader in the use of alternative fuels to reduce waste going ...

获取价格

Cement Manufacturing Process - Chemical Engineering World

2020/9/26 Cement Manufacturing Process. Cement Manufacturing Process. Cement Manufacturing Process. Cement is a material which is used to bind other materials together. Binding means it has an effect of gluing the substances together due to cohesive and adhesive action and then hardens and sets in order to become permanent. Cement is usually not used

获取价格

Production Process - INSEE Cement : Sri Lanka’s leading only

The cement manufacturing process is divided into two types: wet process and dry process, with the dry process being the most commonly used method worldwide. The Palavi process operation follows the dry process and was established in 1969 as a

获取价格

How Is Cement Made? Step-by-Step Guide - BigRentz

2023/12/7 After passing quality control, this mixture, now called raw meal, is ready to move on to the next step in the cement production process. Step 3: Producing Clinker. Trucks transport the raw meal to a production facility where

获取价格

ShapedByConcrete – How Cement is Made

Once crushed, the raw materials are then sent to a laboratory and analyzed – each step of the cement production process is carefully monitored to ensure efficiency and quality. Mixing, grinding, and blending the ingredients ... During this process, cement manufacturers have been a leader in the use of alternative fuels to reduce waste going ...

获取价格

Cement Manufacturing Process - Chemical

2020/9/26 Cement Manufacturing Process. Cement Manufacturing Process. Cement Manufacturing Process. Cement is a material which is used to bind other materials together. Binding means it has an effect of gluing the

获取价格

Production Process - INSEE Cement : Sri Lanka’s leading only

The cement manufacturing process is divided into two types: wet process and dry process, with the dry process being the most commonly used method worldwide. The Palavi process operation follows the dry process and was established in 1969 as a

获取价格

The Cement Manufacturing Process - Thermo Fisher Scientific

2023/12/20 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then they are ...

获取价格

Manufacturing of Portland Cement - Process Applications

2024/11/29 Manufacturing Process of Portland Cement. The manufacturing process of Portland cement starts with grinding and mixing the raw materials at specific proportions. Then the mixture in a kiln is heated at 1350–1500°C to form a sintered product. The steps to be followed for manufacturing Portland cement are as follows:

获取价格

Cement Manufacturing Process

cement manufacturing process . by tizita moges , selamu abule dereje endalamaw . if you need this guide and all other useful excel sheets which will make you master the production , process , maintenance activity in your cement plant kindly click here ...

获取价格

Manufacturing process - Lafarge

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km. The limestone is excavated from open cast mines after drilling and blasting and loaded onto dumpers ...

获取价格

Concrete: Manufacturing Process - BrainKart

Concrete: Manufacturing Process . A good quality concrete is essentially a homogeneous mixture of cement, coarse and fine aggregates and water which consolidates into a hard mass due to chemical action between the cement and water. Each of the four constituents has a specific function. The coarser aggregate acts as a filler.

获取价格

Cement Making Process - Cement Production Process Cement

The comparison data between the wet process cement production line and the new dry process cement production line shows that with the same rotary kiln size (diameter), the production capacity of the cement kiln which adopts the pre-decomposition production process increases more than 200%, the output rises from 27.77kg /m3 to 200.82kg /m3, and ...

获取价格

Production Process CEMEX Philippines

Clinker is the intermediate product used in the manufacturing of cement. There are two primary processes used to manufacture clinker: the dry process and the wet process. Our plants use the dry process, which is more energy efficient. In the wet process, the raw materials are mixed with water to form slurry, which is fed into a kiln.

获取价格

Cement and Concrete Manufacturing Department of Energy

How Do We Decarbonize Cement Manufacturing? Ninety percent of emissions from cement making are from the kiln where limestone and silica (shale and sand) are heated to high temperatures (~1450°C) to chemically create the material, called clinker, necessary in making cement. ... The rest come from the combustion of fossil fuels to reach the high ...

获取价格

Manufacturing of Portland Cement – Process and Materials

3 之 The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C. During this process, these materials partially fuse to form nodular shaped clinker by

获取价格

A Comprehensive Guide to the Cement Manufacturing Process

2024/9/5 The Manufacturing Process of Cement. Now, let’s explore the steps involved in the cement production process in more detail: 1. Mining and Crushing. The process of making cement begins with mining, where raw materials are extracted from quarries. Huge machines called excavators dig the limestone out of the earth.

获取价格