أرسل لنا رسالة

What does it mean to use 200thick limesand bricks

Sand Lime Brick: The Complete Guide - The Brick

Sand lime bricks are typically rectangular and come in various sizes. The most common size in the United States is 8 x 4 x 2.25 inches. In Europe, sizes like 240 x 115 x 71 mm are standard. There are two main categories of sand lime

获取价格

Advantages and Disadvantages of Sand Lime Bricks

Less fire resistant – These bricks do not resist fire as well, which could lead to safety issues in case of a fire breakout.; Not ideal for load-bearing structures – They are not the best for load-bearing structures, meaning they might not be

获取价格

Lime in Construction: Properties, Advantages, and Applications

2 之 Lime, one of the oldest and most versatile building materials, has been used in construction for centuries. Its primary function in construction is as lime mortar, which is crucial for binding bricks, stones, and other materials. Lime’s application ranges from simple masonry work to intricate architectural designs. This article explores the properties of lime, its []

获取价格

Sand-lime brick: composition, types, characteristics, pros and cons ...

The dimensions and properties of sand-lime bricks and stones are described in two standards. GOST 379-95 and GOST 379-2015. The latter provides additional information on silicate blocks, colorants and lightweight fillers that have come into use in recent years. According to the standard, there are the following sizes of sand-lime bricks: Single.

获取价格

Proper Ratio of Lime to Sand - Lancaster Lime Works

2022/4/16 Lime putty must fill the void space within the sand. Too much lime will push the sand particles apart, not enough lime will leave “holes” in the mortar. Both scenarios leave you with a weak mortar or plaster. When mixing

获取价格

Questions and Answers about Lime Mortar - Lancaster Lime Works

Type S lime that is deliberately hard-burned may have a surface area of about 10-11 m2/g (square meters per gram) where a soft-burned lime for use in a lime-only mortar can easily have a surface area of 25-35 m2/g. The lower surface area lime is less reactive. Use this to make a lime mortar it will have low strength and a much longer set time.

获取价格

Sand Lime Bricks or Calcium silicate bricks

Properties of sand lime bricks: It is a very smooth and uniform finish and has an attractive appearance. They are dense, strong, and tough. They are porous therefore free from indigestion. Also, uniform in size, shape, finish, and no

获取价格

What happens when you mix lime and sand together? - Remodel

Sand lime mortar is a type of mortar that is made from a combination of sand and lime. It is a popular choice for interior and exterior walls in historic buildings, where sand lime mortar provides the stability and durability needed for lasting support. Sand lime mortar is composed of a dry mix of sand, hydrated lime, and water.

获取价格

Calcium Silicate Bricks or Sand Lime Bricks for Masonry

🕑 Reading time: 1 minute Calcium silicate bricks are made of sand and lime and popularly known as sand lime bricks. These bricks are used for several purposes in construction industries such as ornamental works in buildings, masonry works etc. Sand lime bricks are popularly used in European countries, Australia and African countries.

获取价格

Bricks, Mud and Lime Restoration: A case study

bricks and roof tiles too. It is usually made by adding sand to the clay and water as the binding material. To reduce the shrinkage and cracks, fine sand, rice husk and fibres are added to these mortars. It is one of the most environment friendly materials used in our monuments and heritage buildings since years.

获取价格

The Impact of Glass Additives on the Functional and

modifications of sand-lime bricks, especially using glass additives ... treatment of the products is around 200°C, the pressure - 1,6-1,8 MPa and the time - up to 8hours (it means: 1h heating ...

获取价格

Bricks, Mud and Lime Mortars in Heritage Restoration: A case study

2024/9/16 Mortar coatings applied to historic buildings and artwork must be compatible with the pre-existing materials, thus contributing with both the restoration and preservation of heritage without ...

获取价格

Calcium Silicate Masonry Units (CSU) Superior Structure

Calcium Silicate Masonry Unit is a precast building material that simultaneously provides structure, thermal and acoustic insulation. These units are produced by mixing lime, sand, and water in a batch process, where the lime must react immediately with the quicklime to develop some early ‘green’ strength before entering the autoclave.

获取价格

Use of Traditional Lime Mortars in Modern Brickwork

lime mortars are stiffer than Portland cement ones. They are also less tolerant of adverse weather during application and curing. • Good bonding: - Yes * • Tolerant of movement: - Yes, but this does not mean that no movement joints are required when lime mortar is used. No authoritative guidance is available on this aspect of design.

获取价格

A masonry of sand-lime brick: advantages and disadvantages

Sand-lime brick is today mostly an industrially manufactured product - natural sand-lime brick, however, is only rarely to be found. The production, however, always causes less cost than the burning of bricks at relatively high temperatures - therefore, sand-lime bricks are often much cheaper as a building material.

获取价格

Sand-lime brick - Articles about construction and repair

Accordingly, you increase transportation costs, but, most worryingly, instead of the thick heavy option, you can buy wet light sand-lime brick and not even know it. Most often, the weight of the block or stone are calculated as the mean value from weighing a small batch of ten pieces.

获取价格

Can You Sand Down Brick? Tips on Sanding Bricks

2022/1/28 In contrast, heavily textured bricks are difficult or even impossible to sand down as they are resistant to abrasion and will simply wear the sandpaper down. However, paint chips can be sanded off on most bricks. If you need to sand down bricks – to remove blemishes, smooth or align them – you may need to use more tools to achieve your goal.

获取价格

Calcium Silicate Bricks – Manufacturing Process Uses

2024/10/25 Materials Used for Manufacturing Calcium Silicate Bricks. Sand- Calcium silicate bricks consist of 88% to 92% of fine sand. Lime- A range of 8 to 12% of calcium silicate bricks consists of lime. Water- Clean water of 0.25% is used to bind sand and lime together. Colour Pigments- A range of 0.2 to 3% of pigments are added as colouring agents ...

获取价格

A masonry of sand-lime brick: advantages and disadvantages

Sand-lime brick is today mostly an industrially manufactured product - natural sand-lime brick, however, is only rarely to be found. The production, however, always causes less cost than the burning of bricks at relatively high temperatures - therefore, sand-lime bricks are often much cheaper as a building material.

获取价格

Sand-lime brick - Articles about construction and repair

Accordingly, you increase transportation costs, but, most worryingly, instead of the thick heavy option, you can buy wet light sand-lime brick and not even know it. Most often, the weight of the block or stone are calculated as the mean

获取价格

Can You Sand Down Brick? Tips on Sanding Bricks

2022/1/28 In contrast, heavily textured bricks are difficult or even impossible to sand down as they are resistant to abrasion and will simply wear the sandpaper down. However, paint chips can be sanded off on most bricks.

获取价格

Calcium Silicate Bricks – Manufacturing Process Uses

2024/10/25 Materials Used for Manufacturing Calcium Silicate Bricks. Sand- Calcium silicate bricks consist of 88% to 92% of fine sand. Lime- A range of 8 to 12% of calcium silicate bricks consists of lime. Water- Clean water of 0.25% is used to bind sand and lime together. Colour Pigments- A range of 0.2 to 3% of pigments are added as colouring agents ...

获取价格

Brick and Mortar are Perfect Partners - But Add Lime

Not all sand looks the same, because the small rock particles that make up the sand are different colors. How does hydrated lime help mortar? Many old masonry buildings were made with a mortar that had abundant quantities of hydrated lime or just lime and sand. Typically the more lime that’s in a mortar, the weaker the mortar is.

获取价格

Sand Lime Blocks Bricks - Saudi Lime

Calcium Silicate Hydrate, known as sand lime blocks or bricks are manufactured by mixing lime, sand, and enough water for the mixture to be molded. They are then dried in an autoclave under high pressure {12-14 bar) and at high temperatures (160 – 200 C’).

获取价格

Study of compressive strength of sand-lime bricks produced with

2022/8/15 The use of the mixture design of experiment technique to study properties of sand-lime bricks has already been used by Kuhnt et al. [15], who conducted mixture-process experiments to determine an optimal components mixture of traditional raw materials that maximizes the compressive strength of bricks. Thus, the aim of this paper is to produce ...

获取价格

The sizes, types, standards of Australian bricks - Architecture

2022/7/12 Sand Lime Bricks are best suited for external walls, like face bricks. Their dimensions are slightly larger than the standard, at 228mm (length) x 127mm (width) x 101mm (height). 5.

获取价格

Should I use sharp sand cement or lime mortar? : r/DIY - Reddit

The wall has stone bricks and is wide at about 45 cm with a cavity. There's also a hidden chimney to the left of the door jamb. Should I build up the wall with sharp sand and cement render or is it better to make a lime render like it originally had?

获取价格

Sand Lime Bricks: A Sustainable Building Material for the Future

2023/6/7 Manufacturing Process of Sand Lime Bricks. The manufacturing process of sand lime bricks is easy and straightforward. The lime and sand are mixed in a specific proportion and then pressed with the help of a hydraulic press. The bricks are then kept in a humid chamber for a specific time to allow them to harden and develop strength. The entire ...

获取价格

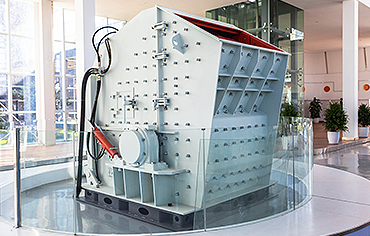

Sand-Lime Bricks and Blocks Technology

Sand Lime Bricks and Blocks Sand-lime brick, also known as calcium silicate brick, is a type of building material made by mixing sand, lime, and water. ... However, on average, the carbon footprint of producing one ton of sand-lime bricks is estimated to be around 200-300 kg of CO2 emissions. This is significantly lower than the carbon ...

获取价格

Installation on lime sand blocks, bricks and aerated concrete masonry ...

Installation on lime sand blocks, bricks and aerated concrete masonry work Blocks with binders (e.g. lime sand blocks) must have reached an age of at least 6 months before tiling (6 months after the production of the block) in order to prevent damage to the tiles, which can be traced back to shrinkage stresses.

获取价格

QUANTITIES CEMENT, LIME SAND REQUIRED PER 1000

6. 8 pockets cement : 1.34m3 sand 5. 8 pockets cement : 5. 8 pockets lime : 1.16m3 sand CLASS III 1: 9 1: 2: 9 4. 7 pockets cement : 1. 41 m3 sand 3.9 pockets cement : 7.8 pockets lime: 1.17m3 sand N.B. For mortar mix requirements for Calcium

获取价格

Lime Wash for Bricks – A Comprehensive Guide - Newline Painting

2021/12/22 Step Four – Limewash Bricks Through Even Application. Using a roller, or paintbrush, apply a thin coat of lime wash onto your bricks and completely cover them. Use a vertical motion from top to bottom, and continue to stir your limewash mixture as you go along. Once limewash has been evenly distributed to your bricks, it will gradually whiten.

获取价格