أرسل لنا رسالة

manufacturing process concrete

Concrete: Manufacturing Process - BrainKart

Concrete: Manufacturing Process . A good quality concrete is essentially a homogeneous mixture of cement, coarse and fine aggregates and water

获取价格

How concrete is made - material, manufacture, making,

Concrete is a hardened building material created by combining a chemically inert mineral aggregate (usually sand, gravel, or crushed stone), a binder (natural or synthetic cement), chemical additives, and water. ... The Manufacturing

获取价格

7 Crucial Steps of the Concrete Manufacturing

2023/5/25 Steps of Concrete Manufacturing Process. The quality of hardened concrete largely depends on the level of attention given at each production stage. A critical aspect of concrete production is the proper

获取价格

How Cement is Made - Portland Cement Association

Cement Concrete. An English bricklayer made the first portland cement early in the 19th century by burning powdered limestone and clay on his kitchen stove. ... While each cement plant may differ in layout, equipment, and appearance, the

获取价格

Concrete Manufacturing Process in modern

2023/5/1 The main Concrete Manufacturing Process is as follows. Batching; Mixing; Transporting; Placing; Compacting; Curing; 1. Batching. It is the main thing in the Concrete Manufacturing Process. The measurement of

获取价格

7 Important Concreting Process - Steps Involved In Manufacturing Concrete

The concreting process or concrete manufacturing process involves a series of steps that transform the basic ingredients – cement, coarse and fine aggregates, and water – into a classic construction material. Each step is crucial in ensuring that the resulting concrete is of high quality and meets the specific requirements of the ...

获取价格

Cement - Extraction, Processing, Manufacturing Britannica

2024/12/22 Cement - Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by

获取价格

Concrete Production, Placement, Curing Process Summary

2021/1/18 In this method, concrete conveys from a central discharge point to formwork. Belt conveyors: It is used to convey concrete horizontally or inclined on the construction site. 4. Placing of concrete: Placing of concrete is the process of deposition of concrete in its required position. Placing of concrete under water is done by various methods.

获取价格

Manufacturing process of concrete (for civil engineering)

2018/2/11 4. Volume batching In this, the measurement of concrete material are taken by volume. It is not a good method for proportioning the material because it is difficult to measure granular material in term of volume. As volume of moist sand in loose condition weight less than same volume of dry compacted sand. However, for unimportant concrete or small job,

获取价格

MANUFACTURING PROCESS OF AAC BLOCK - ResearchGate

2017/9/17 AAC blocks are light weight Aerated Autoclave Concrete Block. It is manufactured through a reaction of aluminium powder and a proportionate blend of lime, cement, and fly ash or sand.

获取价格

Concrete Manufacturing: Block Pipe Process Vaia

The concrete manufacturing process involves gathering ingredients, calibrating their proportions to form concrete. The general mix ratio typically followed in standard concrete block manufacturing is 1:2:3 – 1 part cement, 2 parts sand, and 3 parts aggregate.

获取价格

What Are The Manufacturing Process Of Concrete Process Of

MANUFACTURING OF CONCRETE. While manufacturing concrete, it should be ensured that every batch of concrete has the same proportions. This is a mandatory requirement so as to satisfy two aspects, viz., same workability and uniform strength. In the manufacturing of concrete the following steps are followed: 1. Proportioning of concrete. 2.

获取价格

3.2 Manufacturing Process of concrete - RCET

Fig 1 manufacturing process of concrete 1)Baching of Materials For good quality concrete a proper and accurate quantity of all the ingredients should be used. The aggregates, cement and water should be measured with an accuracy of ± 3 per cent of batch quantity and the admixtures by 5 per cent of the batch quantity.

获取价格

Cement Production: How Cement Is Manufactured CEMEX UK

Concrete Calculator Regenera Solutions. Solutions Project Type Concrete For Tunnelling Agricultural Building Supplies Solutions for ... Calcination is the core portion of the process, in which huge rotary kilns come into play. Inside, at 1400 degrees C, the raw material is transformed into clinker: small, dark gray nodules 3-4 centimetres in ...

获取价格

How is Concrete Made Step by Step: A Comprehensive Guide

Curing is a critical process in concrete construction that significantly impacts the strength, durability, and overall performance of the finished product. ... Sustainable Practices in Concrete Manufacturing. Concrete is an indispensable material in modern construction, yet its production has significant environmental impacts. By adopting ...

获取价格

AAC Blocks Manufacturing Process - Conecc - Conecc Concrete

AAC blocks manufacturing process. Lightweight blocks are a green building product as there is no pollution or waste material in the manufacturing process. ... Autoclaved Aerated Concrete (AAC) is produced by mixing pulverized fly ash, cement, gypsum, lime, water, and a small quantity of aluminium powder, soluble oil, and plastic squeeze. ...

获取价格

3.2 Manufacturing Process of concrete - RCET

Fig 1 manufacturing process of concrete 1)Baching of Materials For good quality concrete a proper and accurate quantity of all the ingredients should be used. The aggregates, cement and water should be measured with an accuracy of ± 3 per cent of batch quantity and the admixtures by 5 per cent of the batch quantity.

获取价格

Cement Production: How Cement Is Manufactured CEMEX UK

Concrete Calculator Regenera Solutions. Solutions Project Type Concrete For Tunnelling Agricultural Building Supplies Solutions for ... Calcination is the core portion of the process, in which huge rotary kilns come into play. Inside, at 1400 degrees C, the raw material is transformed into clinker: small, dark gray nodules 3-4 centimetres in ...

获取价格

How is Concrete Made Step by Step: A Comprehensive

Curing is a critical process in concrete construction that significantly impacts the strength, durability, and overall performance of the finished product. ... Sustainable Practices in Concrete Manufacturing. Concrete is an

获取价格

AAC Blocks Manufacturing Process - Conecc - Conecc Concrete

AAC blocks manufacturing process. Lightweight blocks are a green building product as there is no pollution or waste material in the manufacturing process. ... Autoclaved Aerated Concrete (AAC) is produced by mixing pulverized fly ash, cement, gypsum, lime, water, and a small quantity of aluminium powder, soluble oil, and plastic squeeze. ...

获取价格

Railway Sleepers Manufacturing Process concrete, Wood,steel

2020/6/9 concrete sleepers manufacturing process. concrete sleepers were introduced in the late 1890s but in India, these are manufactured and laid from 1982. Concrete sleepers are of two types monoblock and twin block concrete sleepers. But mostly we prefer Monoblock sleepers, In the railway sleepers manufacturing process, concrete sleepers are mostly ...

获取价格

Precast Concrete Construction - Manufacturing And Types

2024/12/10 Manufacturing Process of Precast Concrete. Moulds can be used to create precast concrete. These moulds can be reused. Concrete can be cast into a reusable mould to create precast concrete, which is then delivered to the construction site. It shortens the construction timetable, improves quality control, and makes the process more efficient.

获取价格

Concrete Manufacturing Process 101: A Comprehensive Overview

2023/7/29 Concrete is a very Important material for the construction industry; We all know it is the backbone of this modern infrastructure. From Skyscrapers to sturdy bridges, concrete plays a crucial role in construction projects of all scales. Understanding the concrete manufacturing process is essential for engineers, Architects and construction professionals

获取价格

Concrete - MIT Climate Portal

2021/1/8 Concrete is among the world’s most consumed materials—second only to water. 1 That’s because its durability, affordability, and availability make it essential to countless construction projects, from bridges, to roads, to buildings. Since concrete is used on such a large scale, it also produces large amounts of heat-trapping greenhouse gases, mostly from a

获取价格

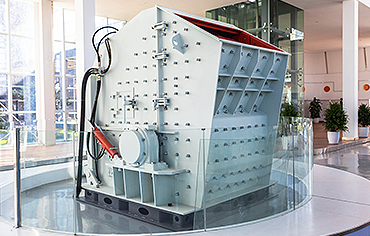

Concrete Manufacturing Processes Valmont Utility

Concrete Manufacturing Process Steel strands. High strength prestressing steel strands are wrapped with spiral wire, and are locked into tension plates at each end of the mold. High-Strength Concrete. The specially formulated, high-strength concrete is placed into the mold. Securing the Mold. The mold is bolted closed, the strand is prestressed ...

获取价格

Concrete-manufacturing process. Download Scientific Diagram

Download scientific diagram Concrete-manufacturing process. from publication: Life Cycle Assessment of concrete manufacturing in small isolated states: the case of Cyprus Life Cycle Assessment ...

获取价格

Manufacturing Process Nordimpianti Concrete Experience

Manufacturing Process. Nordimpianti offers a wide range of production plant to satisfy all requirements ranging from small to large manufacturing output. ... The concrete transport from the batching plant to the casting machine can be carried out in different ways depending on the customer’s requirements and the factory layout.

获取价格

Portland Cement Manufacturing Process - build-construct

4 之 It is the primary ingredient in concrete, which forms the backbone of modern infrastructure. The manufacture of cement involves several steps, each contributing to the final product’s strength, durability, and versatility. This article outlines the history, materials, and step-by-step manufacturing process of Portland cement, with a focus on ...

获取价格

Manufacturing process for concrete roof tiles - Google Patents

a process for manufacturing concrete roof tiles without the use of curing moulds comprising the steps of metering concrete mix into a tile mould, applying pressure to the mix in the mould both to form an uncured tile having a thin, non-planar shape which nevertheless permits packing of the tiles to form a substantially solid block of tiles, and also to dewater and deaerate the mix and

获取价格