أرسل لنا رسالة

average electricity usage of stone crusher

Energy consumption values of each crusher per tonne

Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). Approaches to date have ...

获取价格

(PDF) Engine Load Factors and Fuel Consumption in Stone Quarrying

Thus, it is not known if the factor differs when drilling is performed in different rock types. Load

获取价格

Watching fuel costs in crushing and screening

2016/7/13 Seinäjoen KTK has reached an average consumption of 22litres/ hour with the LT120E jaw crushing plant and 38litres/hour with the LT330D. ... The Warrior 1400XE can also be powered from an electric drive crusher. Keestrack announced at bauma 2016 its new trackmounted cone crusher H4 as the first of its kind in the world. At the heart of the ...

获取价格

average electricity germanyge of hard rocks crusher

Average Electricity Usage Of Stone Crusher. 2020-10-19 Electricity consumption for stone crusher. Average electricity usage of stone crusher Grinding Mill The average size of the crushed rock was 34 by 1 12 inches to 1 by 2 inches. Low Energy Consumption Cone Crushing From Uae. We are concentrating on producing and selling machines such as jaw ...

获取价格

stone crusher plant electricity usage.md

Contribute to dinglei2022/en development by creating an account on GitHub.

获取价格

Electric Rock Crushers Explained: Features, Benefits, and Uses

2024/5/20 Diesel fuel powers most rock crushers at mining quarries, as this eliminates the need for an on-site power source. However, many companies now use hybrid diesel-electric or fully electric crushers. An electric rock crusher does not need a diesel engine. Electricity from the grid powers the motor and all auxiliary drives.

获取价格

Requirements and Energy Consumption of Crusher Plants

2024/3/30 The energy consumption during crushing depends on factors such as the hardness and abrasiveness of the material, the crusher’s efficiency, and the desired output size. Auxiliary Equipment Auxiliary equipment, including conveyors for material transport, screens for sizing and separating aggregates, and hydraulic systems for crusher adjustment ...

获取价格

Energy consumption of a laboratory jaw crusher during normal

2023/12/1 Power consumption and therefore efficiency of crushing equipment are becoming increasingly important mainly due to the continuous and rapid increase of energy costs and efforts to minimise CO 2 emissions (Tromans, 2008, Legendre and Zevenhoven, 2014).In order to meet the Paris Climate Agreement goals, recycling should be maximized by 2050

获取价格

Power Consumption of Cement Manufacturing Plant

Most of the energy usage is in cement production drives end-use, a lot of power is consumed in the processes of cement grinding, raw material crushing, and materials transport, cement transport. The cement industry natural gas consumption is concentrated in the process of heating end use (about 90% of total gas consumption), which involves ...

获取价格

A Comprehensive Guide to Stone Crusher Machines - AGICO

2023/2/22 Stone crusher machines are essential tools in the construction industry, used to crush rocks and stones into smaller pieces for a variety of applications. This guide provides an overview of stone crusher machines, including their history, components, applications, and buying considerations. Whether you are a contractor, landscaper, or building owner, this guide will

获取价格

Development of a model estimating energy consumption values of

2014/2/1 Taking into account formula (5) and table 2, the coefficient of energy of destruction of granite will be 0.446 J/m3 or, in terms of kg, 1.16 kJ/kg.

获取价格

Limestone and Crushed Rock - Department of Energy

In 1978, the National Stone Association reported that out of 20 plants surveyed energy consumption ranged from 20,000 Btu per ton produced for a concrete stone plant to 54,000 Btu per ton for a plant producing fine agricultural limestone as well as grade stone. The average for the 20 plants was 33,500 Btu per ton. 1 Very few studies similar

获取价格

Design and simulation of gear box for stone crushing ball mill

2022/1/1 By replacing the conventional drive system with the new SMH synchronous motor average energy consumption was reduced by 27%. From the investigative interpolation it is estimated that about 23MWh of electricity can be saved annually. ... The Stone crushing ball mill is a robust machine that has the ability to convert the hard materials such as ...

获取价格

Influence of Operating Conditions and Crushing Chamber on Energy

2018/5/1 This paper provides an energy consumption model and explains how the operating conditions and structural parameters of a crushing chamber affect energy consumption. Energy consumption is closely related to compressive pressure and displacement. The relationship between pressure, displacement and structural parameters is discussed. The

获取价格

5 tips for energy efficient and productive cone crushing

2020/4/15 It has been estimated that 5-15% of an aggregate producers’ cost can be associated with the cost of electricity. If cone crusher maintenance is neglected, the result will be a detrimental effect on productivity and an overall higher energy cost per ton of material crushed.

获取价格

Types of Crushers: What you need to know Machinery Partner

The average input size for a secondary crusher ranges from 13" to 4" during this stage. Secondary crushing is especially important for making graded material that is going on to be used on government projects. ... Keeping energy usage and efficiency in mind is always a top consideration. Using the wrong type of crusher can lead to costly delays ...

获取价格

Design and simulation of gear box for stone crushing ball mill

2022/1/1 By replacing the conventional drive system with the new SMH synchronous motor average energy consumption was reduced by 27%. From the investigative interpolation it is estimated that about 23MWh of electricity can be saved annually. ... The Stone crushing ball mill is a robust machine that has the ability to convert the hard materials such as ...

获取价格

Influence of Operating Conditions and Crushing

2018/5/1 This paper provides an energy consumption model and explains how the operating conditions and structural parameters of a crushing chamber affect energy consumption. Energy consumption is closely related to

获取价格

5 tips for energy efficient and productive cone crushing

2020/4/15 It has been estimated that 5-15% of an aggregate producers’ cost can be associated with the cost of electricity. If cone crusher maintenance is neglected, the result will be a detrimental effect on productivity and an overall

获取价格

Types of Crushers: What you need to know Machinery Partner

The average input size for a secondary crusher ranges from 13" to 4" during this stage. Secondary crushing is especially important for making graded material that is going on to be used on government projects. ... Keeping energy usage and efficiency in mind is always a top consideration. Using the wrong type of crusher can lead to costly delays ...

获取价格

Assessment of Stone Crusher Pollution and Its Control

estimated that there are over 12,000 stone crusher units in India. These stone crushers though socio-economically are important sectors yet give rise to substantial quantity of fine fugitive dust emissions which create health hazards to the workers as well as surrounding population by way of causing respiratory diseases (CPCB, 2010). The stone ...

获取价格

Design and simulation of gear box for stone crushing ball mill

2022/1/1 By replacing the conventional drive system with the new SMH synchronous motor average energy consumption was reduced by 27%. From the investigative interpolation it is estimated that about 23MWh of electricity can be saved annually. ... The Stone crushing ball mill is a robust machine that has the ability to convert the hard materials such as ...

获取价格

Analysis of Energy Consumption of Crushing Processes

2017/1/27 The material tested had a cubic shape and average dimension of 90 mm. One-stage crushing was carried out for outlet slot e ... the specific energy demand for crushing of stone is ... It is worth ...

获取价格

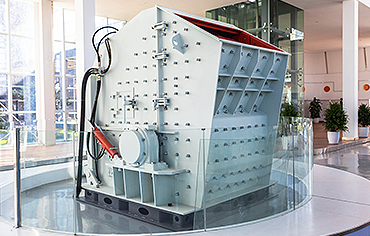

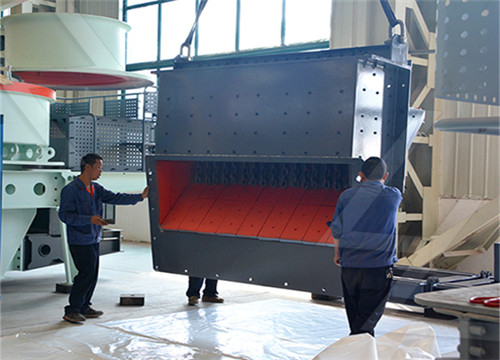

Stone Crusher - Rock Crushing Machine

Low Energy Consumption. Modern stone crushers are engineered to minimize energy consumption during crushing operations, thereby reducing operational costs and environmental impact. Easy Maintenance. Stone crushers are built with user-friendly designs that facilitate easy maintenance and servicing, ensuring minimal downtime and optimal performance.

获取价格

Energy Efficiency Opportunities in the Stone and Asphalt

During the past 25 years, production of crushed stone has increased at an average annual rate of about 3.3%. These projections suggest that vast quantities of crushed stone and sand and ... Optimizing blasts to yield smaller rocks would reduce crusher plant energy consumption. Some of the methods that can be used to improve the shot-rock yields ...

获取价格

Environmental Guidelines for Stone Crushing Units - py

Stone crushing units use different types of crushers for secondary crushing. Granulator or cone crusher is usually used for secondary crushing. 3.4 Screening: From secondary crusher, crushed stones are transferred for screening through a conveyor belt. Screening is the process for segregating products

获取价格

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014/9/1 It is well known and taken for granted that the efficiency of energy use by comminution (i.e. breaking, crushing, grinding) equipment is very low, typically less than 10%. ... Bond work index theory represents an average value on size reduction and energy usage per unit of mass, but represents a fair approximation of a comminution process ...

获取价格

Average Household Electricity Usage in 2024 [kWh per Month]

2023/1/27 Your electricity bills will directly depend on the amount of electricity that you use every month so the first thing you should do is to calculate your average monthly electricity usage. According to the U.S. Energy Information Administration, the average U.S. household consumed approximately 877 kWh per month in 2019 but it can vary from ...

获取价格

How much electricity does a granite cone crusher use per hour

How Much Electricity Does A TV Use 2024 Eco Energy Geek Based on an average cost of electricity in the US of 14 cents per kWh the average TV will cost cents per hour to run However a smaller TV will cost only cents per hour and a larger TV will cost as much as cents per hour You can use the following calculator to work out how much your ...

获取价格

Stone Crusher Plant Setup Cost: Factors, Estimate, and Ways to

2023/2/24 Estimated Cost of Setting Up a Stone Crusher Plant. The cost of setting up a stone crusher plant varies depending on the factors mentioned above. Generally, the estimated cost to set up a stone crushing plant ranges from $10,000 to $1,000,000. The capital needed to set up a stone crusher plant generally depends on the following factors:

获取价格