أرسل لنا رسالة

nickel crushing process

The Comprehensive Guide to Nickel Processing - Mining-pedia

2 Types of Nickel Ore: Processing Methods and Equipment

Process Flow of Copper-Nickel Sulfide OreProcess Flow of Nickel Oxide OreConclusionA complete copper-nickel sulfide ore processing production line is crushing, grinding, flotation, and tailings treatment.在ftmmachinery上

The Guide to Nickel Processing Methods Mining Pedia

2024/10/24 The beneficiation process of nickel sulfide ore mainly adopts flotation method, which is suitable for the separation of fine-grained nickel sulfide ore. The specific process flow

获取价格

Nickel Processing Flow: Comprehensive Guide Mining

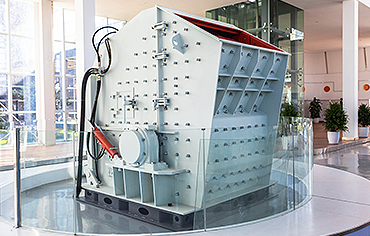

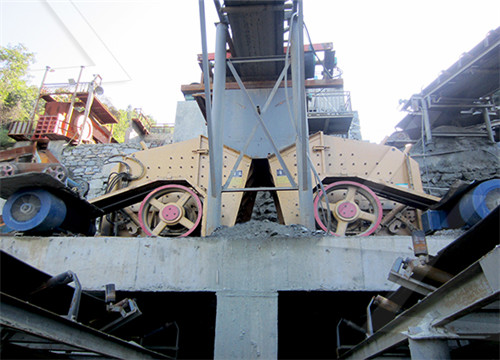

3 之 1. Process: The mined ore is reduced in size using crushers to ensure efficient processing. Screening separates materials by size, removing unwanted debris or oversized rocks. 2. Key Equipment: Jaw Crushers: For initial

获取价格

Nickel Ore Processing Plant - JXSC Mineral

After the vibrating screen screening, the materials under the screen enter the grinding process while the screened materials enter the fine-crushing process. And select the cone crusher for the fine-crushing operation. 2. Grinding

获取价格

Crushing and grinding process for treating nickel-copper sulfide ore

The invention discloses a crushing and grinding process for treating nickel-copper sulfide ore, and belongs to the technical field of metal mineral processing. The grinding process comprises the

获取价格

Nickel Formation and Manufacturing Process - MFG Shop

2024/12/10 For laterite nickel ores, the process starts with crushing and grinding the ore, followed by high-pressure acid leaching (HPAL) to dissolve nickel and cobalt. The solution is

获取价格

Advanced study on the extraction of Nickel from its ores

Nickel production process 2.1.Laterite processing 2.2.sulfide processing 2.3.Ni Secondary resources 3. Disadvantages and alternative technologies 4. ... high ice nickel crushing

获取价格

Extraction of Nickel Nickel Ore Mining Mining

2019/3/20 The extraction of nickel process generally consists of crushing, sieving, washing, re-selection, grinding, and slurry concentration, or the nickel leaching method. The target element nickel distribution varies with the nature

获取价格

How To Operate Nickel Crushing - stone-crushing

Understanding Nickel Crushing: Nickel crushing is an essential process in the extraction of nickel from its ore. It aims to break down large chunks of nickel ore into smaller, more manageable

获取价格

Kambalda Nickel Concentrator Primary Crushing

Project Details Process 26 was engaged by Cape Crushing to design and construct a 1.5 Mtpa primary crushing circuit at its Kambalda Nickel Concentrator, operated on behalf of BHP Billiton Nickel West. Process 26 performed all civil,

获取价格

Nickel Ore Beneficiation And Equipment - JXSC

6 之 (2) Nickel laterite ore in nickel oxide ore has high iron content, low silicon and magnesium content, and 1-2% nickel content; while nickel silicate ore has low iron content, high silicon and magnesium content, and 1.6-4.0% nickel

获取价格

Hydrometallurgical nickel and cobalt plants and processes

The leaching process results in an aqueous nickel and/or cobalt sulfate solution. This solution is further treated through iron, manganese, and other impurity-removal and solvent-extraction stages. The solid residue from the leaching is a cake

获取价格

The Guide to Nickel Processing Methods Mining Pedia

2024/10/24 The beneficiation process of nickel ore is the process of extracting nickel metal from nickel ore, which varies depending on the type and composition of the ore. This article will introduce the nickel ore beneficiation process and key processes in detail. ... The specific process flow is as follows: 1. Crushing and screening. The raw ore is ...

获取价格

Nickel Processing Flow: Comprehensive Guide Mining Pedia

3 之 1. Process: The mined ore is reduced in size using crushers to ensure efficient processing. Screening separates materials by size, removing unwanted debris or oversized rocks. 2. Key Equipment: Jaw Crushers: For initial crushing. Cone Crushers: For secondary and fine crushing. Vibrating Screens: To classify crushed materials into specific size ...

获取价格

Numerical simulation of atomization process of nickel

For the crushing process, the TAB model is used. 3. Results and discussion ... N UMERICAL SIMULATION OF ATOMIZATION PROCESS OF NICKEL-BASED ALLOY POWDERS PREPARED BY VACUUM INDUCTION MELTING GAS

获取价格

Nickel Ore Beneficiation Plant - JXSC Machinery

Nickel ores mainly include copper-nickel sulfide ore and nickel oxide ore (laterite nickel ore). The most important is the nickel ore flotation process, magnetic separation and gravity separation are usually auxiliary beneficiation methods.. We can customize nickel ore beneficiation process and equipment to achieve comprehensive utilization of resources and economic benefits.

获取价格

Extraction of Nickel Nickel Ore Mining Mining Equipment for

2019/3/20 The extraction of nickel process generally consists of crushing, sieving, washing, re-selection, grinding, and slurry concentration, or the nickel leaching method. The target element nickel distribution varies with the nature of the ore, mostly contained in fine-grained grades. For example, the nickel minerals of the Ramu laterite mine in Papua ...

获取价格

nickel ore gravity beneficiation process Mining Quarry Plant

2013/8/29 Nickel ore dressing process mainly consists of: 1, Crushing is three sections and a closed-circuit process and mainly refers to primary crushing, secondary crushing Nickel Ore Processing Plant Nickel ore beneficiation is a complex process;

获取价格

Red clay nickel calcination process - MECRU Heavy Industry

The process of calcination of the laterite nickel ore rotary kiln can be divided into the following steps: laterite nickel ore; water grinding; slurry filtration; addition of limestone and anthracite—mixing by rod mill; ... Suitable for limestone, sandstone and other medium and low hardness ore sand crushing.

获取价格

Numerical simulation of atomization process of nickel-based

2020/6/29 ANSYS Fluent 19.0 software is used to numerically simulate atomization process in the production of nickel-based alloy powders by VIGA. The gas flow field in the atomizing chamber and atomization ...

获取价格

The Best Mining Equipment for Philippines Nickel Ore You

2023/2/15 The crushing process is necessary because when raw laterite nickel ore is excavated, it is often accompanied by columnar rocks with incomplete weathering and with large size. After crushing, the huge block of nickel ore would be reduced to a small size, which ideally avoids screen mesh blocking. A Cone crusher is the best machine to crush ...

获取价格

/sbm rotary nickel screen process flow chart.md at master

Nickel Mining Calcining Process stern1900 nickel mining calcining process Solution for ore mining.nickel mine process chart Crusher South Africa nickel ore processing flow chart iron ore crusher calcination process flow diagram philippines Get more.nickel crushing and screening process visitlanka website.Large roasting restore the rotary ...

获取价格

BHP Ravensthorpe Nickel Operation, Australia - Mining

2008/8/13 Crushing and pressure acid leaching, partial neutralisation and precipitation. Employment. 650. Expected Mine Life. ... The Ravensthorpe Nickel Operation (Australia) was sold by BHP Billiton to First Quantum Minerals Australia on 9 December 2009. ... and a hydrometallurgical process plant to produce up to 50,000t of contained nickel and 1,400t ...

获取价格

Numerical simulation of atomization process of

2020/6/29 ANSYS Fluent 19.0 software is used to numerically simulate atomization process in the production of nickel-based alloy powders by VIGA. The gas flow field in the atomizing chamber and atomization ...

获取价格

The Best Mining Equipment for Philippines Nickel

2023/2/15 The crushing process is necessary because when raw laterite nickel ore is excavated, it is often accompanied by columnar rocks with incomplete weathering and with large size. After crushing, the huge block of

获取价格

/sbm rotary nickel screen process flow chart.md at master

Nickel Mining Calcining Process stern1900 nickel mining calcining process Solution for ore mining.nickel mine process chart Crusher South Africa nickel ore processing flow chart iron ore crusher calcination process flow diagram philippines Get more.nickel crushing and screening process visitlanka website.Large roasting restore the rotary ...

获取价格

BHP Ravensthorpe Nickel Operation, Australia - Mining

2008/8/13 Crushing and pressure acid leaching, partial neutralisation and precipitation. Employment. 650. Expected Mine Life. ... The Ravensthorpe Nickel Operation (Australia) was sold by BHP Billiton to First Quantum Minerals Australia on 9 December 2009. ... and a hydrometallurgical process plant to produce up to 50,000t of contained nickel and 1,400t ...

获取价格

Limestone Crushing Process - JXSC Mineral

About Limestone. Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite. It is a kind of stone widely found in nature. Limestone can be directly processed into stone using crushing equipment and fired into quicklime. Quicklime absorbs moisture or adds water to become hydrated lime.

获取价格

Tati Nickel - DRA Global

DRA was contracted by Norilsk Nickel to provide a complete EPCM service for the design and construction of a nickel pre-concentrate DMS plant and associated crushing and screening systems for the Tati Nickel Mine located in Botswana. The $161 million Tati Nickel pre-concentration plant was designed to process 12 million tonnes of ROM ore per ...

获取价格

NICKEL VALUE CHAIN - RAW MATERIAL OUTLOOK

This process uses crushing, grinding, ˚otation and/or magnetic seperation to increase the nickel content. ... process chain. Nickel is converted via smelting and re˜ning processes into '˜rst-use' components, like stainless steel or alloys, that go on to be used in product

获取价格

Nickel Mining and Processing General Kinematics

2014/4/10 The Nickel Mining Process. It’s not unexpected that the mining processes for nickel differ because nickel is found in two quite different forms of ore. Although some deposits were mined using open pits in the early phases, sulfide deposits are mainly mined using underground techniques similar to copper. Laterite mining is essentially an earth ...

获取价格

Crushing Non-Ferrous Metal Ores: Processing Methods and

2024/9/9 Laterite: Often a source of nickel. The Importance of Crushing in Ore Processing. Crushing is a critical process in the extraction of non-ferrous metals from their ores. It involves breaking down large ore bodies into smaller, manageable sizes, which facilitates more efficient processing. ... The crushing process for non-ferrous metal ores ...

获取价格

The HPAL Process - Total Materia

The process starts with crushing, followed by screening. In this step, it is commonly evaluated if the ore can be concentrated (beneficiated) by screening, where the enriched-silica fraction is separated from the ore. ... Development of technical and economical parameters affecting process selection to treat nickel laterite ores, Universidade ...

获取价格

Process Products - Euronickel Industries

Process. The plant is comprised of two production lines, each with a rotary kiln and an electric furnace. Imported nickel ore is processed through various stages – crushing, drying, milling and pelletizing – before it is reduced in rotary kilns and smelted in the electric furnaces. Various refining and finishing processes are then ...

获取价格

Advanced study on the extraction of Nickel from its ores

Nickel production process 2.1.Laterite processing 2.2.sulfide processing 2.3.Ni Secondary resources 3. Disadvantages and alternative technologies 4. ... high ice nickel crushing process. The main pyrometallurgical processes include flash smelting and molten pool smelting. Flash smelting is a high-temperature (1 450 ~ 1 550 ° C) reaction tower ...

获取价格

Copper Ore Processing Plants, Flow And Equipment

6 之 Including copper ore crushing, screening, grinding, grading and other processes. The purpose of this process is to separate useful minerals from gangue mineral monomers, and to dissociate various useful minerals from each other 1. Crushing process The copper ore that needs to be processed must first go through the crushing process. The ...

获取价格

nickel smelting and crushing process.md

Contribute to dinglei2022/en development by creating an account on GitHub.

获取价格