أرسل لنا رسالة

vertical roller mill roller seal air

Design, installation and maintenance of mechanical seals for

2024/11/20 2 Mechanical seal design of vertical roller mill bearing. The labyrinth seal

获取价格

Vertical roller mill - Hengtu Machinery

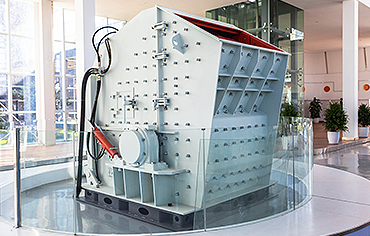

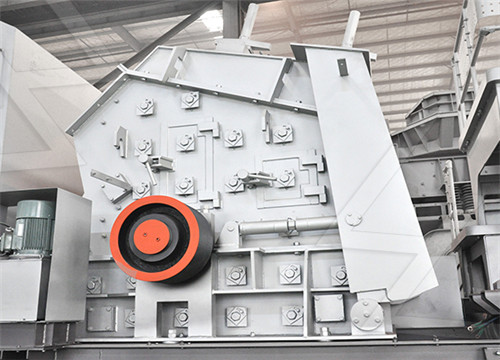

Reliable roller air seals eliminate unnecessary airflow into the mill. The special sealing design of the roller bearing prevents dust from penetrating. A robust gear reducer is used to ensure efficient and stable power transmission. Brief

获取价格

OK vertical roller mill - Environmental-Expert.Com

- OK vertical roller mills use 30-50% less energy than ball mill systems ... Air inlet 1 OK mill 2

获取价格

quadropol® vertical roller mill - thyssenkrupp Polysius

As no dust can get in, there is no longer any need for a sealing air fan. Accessibility is excellent and it is possible to carry out small maintenance work easily without the necessity to remove the roller unit. ... Vertical roller mill

获取价格

Optimisation of the performance of a new vertical roller mill by ...

2024/1/15 An industrial-scale vertical roller mill (M600) was analysed for air flow in this

获取价格

quadropol® vertical roller mill - thyssenkrupp Polysius

As no dust can get in, there is no longer any need for a sealing air fan. Accessibility is excellent and it is possible to carry out small maintenance work easily without the necessity to remove the roller unit. ... Vertical roller mill

获取价格

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newly-built] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200t-RM/h] [1US$=¥110] Related matters ...

获取价格

Operation Manual: HRM1700M Vertical Roller Coal Mill

The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill. It describes the mill's technical parameters, components, structure, working principles, and installation process. Key aspects include

获取价格

An investigation of performance characteristics and energetic ...

2020/8/12 Altun et al [15] explored the influence of the parameter settings of a vertical roller mill on grinding performance and demonstrated the influence of grinding pressure values on the size and mass ...

获取价格

Vertical roller mill - Hengtu Machinery

Reliable roller air seals eliminate unnecessary airflow into the mill. The special sealing design of the roller bearing prevents dust from penetrating. A robust gear reducer is used to ensure efficient and stable power transmission. Brief description of vertical roller mill operation:

获取价格

Vertical raw mill pradeep kumar PPT - SlideShare

2013/5/15 • 2.1 vertical roller mill vibration is too large: (1) Feed uneven, when the mixture into the vertical roller mill over the powder, the vertical roller mill's loading rate, leading to the vertical roller mill on the thin material, and even disc direct contact with the roller,resulting in mechanical milling; when into the vertical roller mill ...

获取价格

CN203124037U - Novel air seal for grinder roll of vertical roller mill ...

The utility model provides a novel air seal for a grinder roll of a vertical roller mill. The novel air seal can effectively prevent dust and particles from entering the grinder roll. The novel air seal is characterized in that a vent hole is drilled in a grinder roll shaft; a vent groove is machined in a shaft sleeve; air holes are uniformly distributed in the circumferential direction of the ...

获取价格

Vertical Roller Mills - LNV TECHNOLOGY

Vertical roller mills are large grinding machines developed, designed and manufactured by Sinoma-tec ... A Vertical mill consists mainly of motor, planetary gearbox, grinding table, grinding rollers, rocker arms, mill stand, mill housing, separator, water spray unit, pressure device, lubrication system, and rocker arm sealing. Structural ...

获取价格

Vertical Roller Mill for Cement Raw Material SINOMALY

Vertical Roller. SINOMALY produces cement raw material grinding mills in various specifications. These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d. The vertical grinding mill is utilized for the grinding of raw materials, mixed cement, and slag powder.

获取价格

Optimisation of the performance of a new vertical roller mill by ...

2024/1/15 An industrial-scale vertical roller mill (M600) was analysed for air flow in this study. This led to proposed modifications, which were implemented in a new mill design (M350). The M600 mill can operate under continuous mode and is used for fine grinding of materials. The design of this mill is depicted in Fig. 1. It comprises six vertical ...

获取价格

Design, installation and maintenance of mechanical seals for vertical ...

2024/11/20 2 Mechanical seal design of vertical roller mill bearing. The labyrinth seal cover adopts a multi-pass sealing structure (see Figure 1) to effectively prevent the leakage of liquid or gas and prevent dust and impurities from entering the bearing. In addition, in order to further improve the sealing effect, an O-ring is added to the contact ...

获取价格

Vertical Roller Mills used for the comminution of mineral ores

Vertical roller mills are traditionally air-swept mills. A VRM applies a compressive force using fixed rollers pressing downwards on a rotating grinding table. The material to be ground is fed into the centre of the grinding table via a feed chute. From there it forms a material bed which passes under the rollers and

获取价格

An investigation of performance characteristics and energetic ...

2020/8/12 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources. Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass flow rates for all used coal.

获取价格

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

the capacity of grinding and drying of mill. The grindability affects the capacity of grinding, type of mill and roller pressure. The capacity of the mill is calculated Using G K * D 2.51 Where, G is capacity of the mill, K1 is roller mill coefficient and D is table diameter. 2. PROCESS CONTROL OF VRM The conventional control system of VRM

获取价格

Design, installation and maintenance of mechanical seals for vertical ...

2024/11/20 2 Mechanical seal design of vertical roller mill bearing. The labyrinth seal cover adopts a multi-pass sealing structure (see Figure 1) to effectively prevent the leakage of liquid or gas and prevent dust and impurities from entering the bearing. In addition, in order to further improve the sealing effect, an O-ring is added to the contact ...

获取价格

Vertical Roller Mills used for the comminution of mineral ores

Vertical roller mills are traditionally air-swept mills. A VRM applies a compressive force using fixed rollers pressing downwards on a rotating grinding table. The material to be ground is fed into the centre of the grinding table via a feed chute. From there it forms a material bed which passes under the rollers and

获取价格

An investigation of performance characteristics and energetic ...

2020/8/12 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources. Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass flow rates for all used coal.

获取价格

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

the capacity of grinding and drying of mill. The grindability affects the capacity of grinding, type of mill and roller pressure. The capacity of the mill is calculated Using G K * D 2.51 Where, G is capacity of the mill, K1 is roller mill coefficient and D is table diameter. 2. PROCESS CONTROL OF VRM The conventional control system of VRM

获取价格

Atox Vertical Roller Mill, Maintenance and Repair

The document discusses maintenance and repair of an ATOX Vertical Mill. It describes systematic and condition-based maintenance approaches. Systematic maintenance consists of regular cleaning, lubrication and visual inspections. Condition-based maintenance monitors factors like vibration levels and temperatures during operation and performs more thorough inspections

获取价格

A Comparison of Three Types of Coal Pulverizers - Babcock

Pressurized air seals between the rotating mill and inlet/outlet boxes prevent leakage of coal dust or air from the mill. Each mill is completely enclosed in an insulated sound-attenuating housing ... The vertical roller mill (VRM) shown in Figure 4 is an air swept, medium-speed, vertical pulverizer with integral classifier. It pulverizes coal ...

获取价格

Coal mill, gypsum mill, clay mill, etc. Pfeiffer MPS mills

The MPS vertical roller mill - built to last, reliable and energy-efficient - is the optimum solution when it comes to performing several process steps in one unit. Advantages of the MPS vertical mill ... (air or hot gas) flow through this nozzle ring, take up the ground and dried material and convey it to the classifier where it is separated ...

获取价格

RAYMOND® ROLLER MILLS - Thomasnet

Raymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800’s. These early machines were the forerunner of the heavy-duty, rugged ring-roll mill manufactured today. The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materials.

获取价格

CN104815744A - Vertical roller mill grinding roller protection

The vertical roller mill grinding roller protection sleeve has the advantages that in a high-density dust environment in a mill, the surface of a grinding roller can be effectively protected from scouring abrasion, and two sides of a middle shell grinding roller sealing door and a lower steel plate can be prevented from being reversely scoured ...

获取价格

ATOX12.5 ATOX13.5 ATOX15.5 ATOX17.5 Raw Coal Vertical Roller Mill

We are exporter of FLS ATOX and OK series of vertical roller mill spare parts. send mail to Sales@reamor for your product inquiry. ... For Sealing Air Lubrication Oil: Atox Raw Mill: Spherical plain bearing GE 240 ES-2RS: 2: Atox Raw Mill: Sealing sphere: 3.100634: 2: Atox Raw Mill: Stop collar: 3.103095: 4: Atox Raw Mill: Wear sleeve:

获取价格

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for dry-grinding the above-mentioned grinding stock. Loesche has

获取价格

Chapter Six: Some Operating Guidelines - Vertical Roller Mill

2022/4/6 An interesting historical fact is that a vertical roller mill uses the same operating principle as the pistrium or pistrinum, an antique Roman grain mill. The largest grain mills used worked a ...

获取价格

3 Necessary Cement Milling Comparison Ball Mill, Vertical Roller Mill

2020/11/5 Vertical roller mill. Vertical roller mill, also called cement vertical mill, it grinds raw materials by the movement between grinding roller, millstone and grinding device. In general the grinding efficiency of vertical roller mill is 80% as much power as cement ball mill, reduce about 30% power consumption.

获取价格

Vertical Mill Spare Parts - Industrial Spare Part Solution

Supplier of Vertical Roller Mill Spare Part,Chia,Denmark,Germany.Guide vanes,Air guide cone,Segmented grinding roller. MobileWhatsapp +86-17749519279; sales@reamor; Home; ... 16 Connection to mill house. 17 Air and material seal or tension rod 18 Tension rod. 19 Hydraulic cylinder with accumulators. 20 Variable speed drive or separator. 21 ...

获取价格