أرسل لنا رسالة

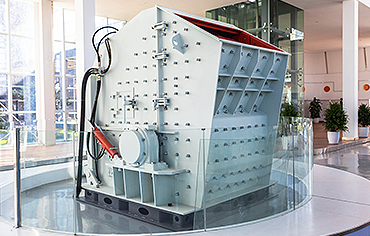

Impact crusher structure Figure area

DESIGN AND ANALYSIS OF IMPACT CRUSHERS - National

crusher,Jaw crusher and Impact crusher. Our objective is to design various components of an

获取价格

Crushing Plant Design and Layout Considerations - 911

• Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s

获取价格

Impact Crusher Working Principle - 911Metallurgist

2015/6/23 Test Procedures for the Characterization of Crusher Performance. The Bond Impact Work Index method has been an industry

获取价格

Impact Crusher - an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw

获取价格

Specifications of the crusher. Download Scientific Diagram

Download scientific diagram Specifications of the crusher. from publication: Numerical

获取价格

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT

An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical

获取价格

(PDF) Design of Impact stone crusher machine

2019/5/31 Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher. The main objective is to design impact stone crusher.

获取价格

Research and Design of High Efficiency Superfine Crusher

Its structure diagram is shown in Figure 1 (M25). 3.2.1 Involute impact plate design . The

获取价格

Impact Crusher

The JOYAL Impact Crusher is used for primary, secondary and fine crushing of all kinds of

获取价格

Introduction to the structure type of impact crusher

2023/11/2 The selective crushing capacity of the impact crusher on the material during

获取价格

How does an impact crusher work? - RUBBLE MASTER

Impact crushers reduce mineral materials such as concrete, asphalt and natural rock in size to produce a valuable commodity product. A fast spinning rotor throws the material against a solid stationary impact wall. The striking and impacting

获取价格

Impact crusher PF1315 - Aggregate Rock Crushing Equipment

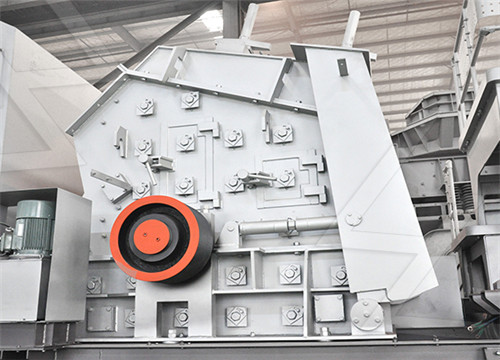

2023/11/10 Impact crusher PF1315 Technical data. Model:PF-1315 Rotor size:Φ1320×1500mm Feeder opening size:860×1520mm Max feeding size:500mm Capacity:100-280t/h Motor power: 160kw or 220kw Impact crusher structure. The impact crusher PF1315 is mainly composed of main frame, impact rack, rotor rack, impact plate and

获取价格

Jaw crusher layout (supporting structure highlighted in red,

In the paper investigations of the causes of fatigue cracks of the jaw crusher supporting structure are presented. The problems have appeared after short time of operation of the new crushing ...

获取价格

Load and wear experiments on the impact hammer of a

An impact hammer consists of 22 carbon tungsten alloy blocks, which are welded to the steel surface by specialty technology. A simulation test was created to determine the maximum impact load area

获取价格

A REVIEW ON STUDY OF JAW CRUSHER - 911 Metallurgist

breakage in impact crushers” Centre Terre et Pierre, 55 Che´e d‟Antoing, Tournai, in 2004 worked a phenomenological model that predicts the size distribution of the product issued from impact ... crusher structure diagram shown in figure 6 requirement for the Figure 6 Single toggle jaw crusher jaw crusher structure

获取价格

Impact Crusher

impact equipments via the high-speed impact of the board hammer. These materials will be re-crushed after rebounding into the scale board. The large materials are crushed into small pieces until it becomes the specified granularities. The end products come out from the base of the impact crusher. WORKING PRINCIPLE STRUCTURES First Stage Impact ...

获取价格

Figure 1. Mechanical structure of roller crusher

The experiment consisted of three parts: the login-stage, the experiment and an after-survey. The experiment starts with 6 single-player Tower of Hanoi games to enable learning and to induce ...

获取价格

CN102179274A - Impact crusher - Google Patents

As shown in Figure 2, the impact baffle plate device is made up of grillage 6, tooth plate 7, L type briquetting 8.Grillage 6 is the steel frame construction of a welding, and design has two hinged axis holes 10 at the back, can use connecting axle that grillage 6 and disintegrating machine lower body are fixed up.Designed the structure of a ...

获取价格

Collision Energy Analysis within the Vertical Shaft Impact

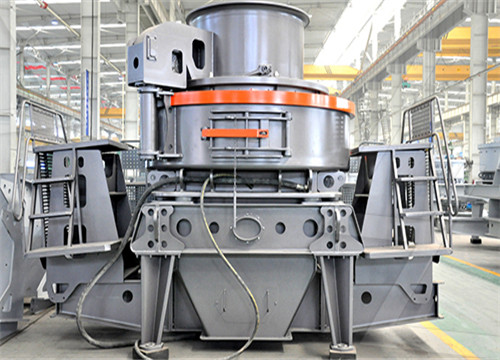

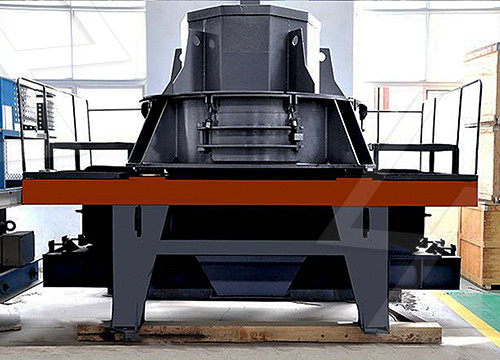

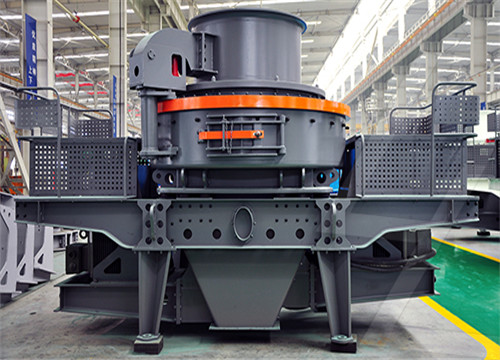

2. STRUCTURE PRINCIPLE OF A VSI CRUSHER The rotor is an essential part of the crusher. The PL8500 VSI crusher is investigated in this paper, whose rotor is composed of a rotor body, separating cone, guide plate, and throwing tip, as shown in Figure 1. The schematic diagram of the working principle of the crusher is shown in Figure 2. When the ...

获取价格

Collision Energy Analysis within the Vertical Shaft Impact

2. STRUCTURE PRINCIPLE OF A VSI CRUSHER The rotor is an essential part of the crusher. The PL8500 VSI crusher is investigated in this paper, whose rotor is composed of a rotor body, separating cone, guide plate, and throwing tip, as shown in Figure 1. The schematic diagram of the working principle of the crusher is shown in Figure 2. When the ...

获取价格

What is an Impact Crusher and How Do They Work?

Impact crushers efficiently process various minerals to reduce the ore to smaller sizes for further processing. • Manufacturing High-quality Cubical Aggregates. In the production of concrete and asphalt, where the shape and size of the aggregate are critical, impact crushers are valued for their ability to produce precisely shaped end ...

获取价格

Vertical shaft impact crusher. Download Scientific Diagram

The compaction quality is affected by many factors encompassing shape and angularity of aggregates, the content of asphalt binder, the temperature of compaction and gradation types, etc. [7][8][9 ...

获取价格

Collision Energy Analysis within the Vertical Shaft Impact Crusher ...

2024/2/2 2. Structure Principle of a VSI Crusher. The rotor is an essential part of the crusher. The PL8500 VSI crusher is investigated in this paper, whose rotor is composed of a rotor body, separating cone, guide plate, and throwing tip, as shown in Figure Figure1 1.The schematic diagram of the working principle of the crusher is shown in Figure Figure2 2.

获取价格

EP0607977A2 - Rotor blade structure for vertical shaft impact crusher ...

A rotor blade structure for a vertical shaft impact crusher which enables the lifetime of blades to increase and facilitates maintenance. In the early stage of wear, it takes place by collision between a blade body (2) of each blade (1), particularly teeth (4) provided thereon, and raw stone. Accordingly, in this stage, rods (9) buried in the blade body (2) do not collide with raw stone.

获取价格

What is an Impact Crusher and How Do They Work?

Impact crushers efficiently process various minerals to reduce the ore to smaller sizes for further processing. • Manufacturing High-quality Cubical Aggregates. In the production of concrete and asphalt, where the shape and size of the

获取价格

Vertical shaft impact crusher. Download Scientific

The compaction quality is affected by many factors encompassing shape and angularity of aggregates, the content of asphalt binder, the temperature of compaction and gradation types, etc. [7][8][9 ...

获取价格

Collision Energy Analysis within the Vertical Shaft Impact Crusher ...

2024/2/2 2. Structure Principle of a VSI Crusher. The rotor is an essential part of the crusher. The PL8500 VSI crusher is investigated in this paper, whose rotor is composed of a rotor body, separating cone, guide plate, and throwing tip, as shown in Figure Figure1 1.The schematic diagram of the working principle of the crusher is shown in Figure Figure2 2.

获取价格

EP0607977A2 - Rotor blade structure for vertical shaft impact crusher ...

A rotor blade structure for a vertical shaft impact crusher which enables the lifetime of blades to increase and facilitates maintenance. In the early stage of wear, it takes place by collision between a blade body (2) of each blade (1), particularly teeth (4) provided thereon, and raw stone. Accordingly, in this stage, rods (9) buried in the blade body (2) do not collide with raw stone.

获取价格

The vertical shaft impact crusher. (1) Feeder; (2) splitter; (3) rotor ...

A geometric model of rotors is established on the basis of the structure of vertical shaft impact crusher. The dynamic simulation of the rotor is carried out by using the discrete element software ...

获取价格

Working principle of impact crusher - crusher

The process of material crusher impact crusher ( see Figure Impact Crusher 2 ). impact-crusher-2. Impact Crusher is a broken machine which use of impact energy to crushing material. When the machine works, under the driving of the motor, the rotor high-speed rotation, the material into the plate hammer function area, and the impact of the rotor ...

获取价格

Impact Crusher - Impact Rock Crusher AGICO Cement Plant

Impact crusher is a kind of crushing machine which uses impact energy to break materials. It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm and compressive strength not exceeding 350 mpa. ... Impact Crusher Structure. The impact crusher consists of impact rack, impact plate, main shaft, blow ...

获取价格

What Is an Impact Crusher and What Can It Do for You?

2019/12/6 The mechanical structure of an impact crusher is defined by its rotor, the primary instrument for breaking apart material. The rotor is set among mounted plates, anvils, or aprons, inside a heavy housing; these aprons or anvils serve to bear the impact of the materials being processed and further break them apart.

获取价格

Modeling and Optimization of a Vertical Shaft Impactor for

Vertical Shaft Impact crushers have been used for a long time to reduce the size of particles and to give particles a cubical shape profile. Very few investigations have been performed on the inner workings of the VSI crusher and even fewer attempts have been made to model the particle breakage and collisions that occur inside it.

获取价格

Understanding the Impact Crusher Working Principle for ... - AGICO

2023/2/23 What is an Impact Crusher? Impact crushers, also known as impactors or horizontal shaft impact crushers, are crushing machines that use the principle of impact crushing to crush materials.They are commonly used in mining, construction, and recycling industries to produce high-quality cubical aggregates from various materials, including hard rock, soft rock,

获取价格

Gyratory crusher (adapted from ThyssenKrupp, 2005).

Download scientific diagram — Gyratory crusher (adapted from ThyssenKrupp, 2005). from publication: A Gyratory Crusher Model and Impact Parameters Related to Energy Consumption The objective ...

获取价格

Figure 9. Structure of the crusher performance model.

Figure 9 a structure for analysis of a cone crusher is shown (Paper D). To calculate the product size distribution of the output from a cone crusher according to the suggested structure, two main ...

获取价格

Crusher - an overview ScienceDirect Topics

Fault diagnosis of mechanical equipment in high energy consumption industries in China: A review. Yongjian Sun, ... Xiaohong Wang, in Mechanical Systems and Signal Processing, 2023. 2.1.1 Crusher. Crusher is a widely used gravel machine, which is mainly used in the crushing of granite, limestone, quartz and other stones. The crusher can crush the stone into fine particles

获取价格

The equipment applied to physical recovery (A) Wet impact crusher ...

The devices utilized in the application of physical recovery technology are summarized in Figure 5, which include the wet impact crusher, low-temperature ball mill, magnetic roller, modified ...

获取价格