أرسل لنا رسالة

how to calculate ball charge in sag mills

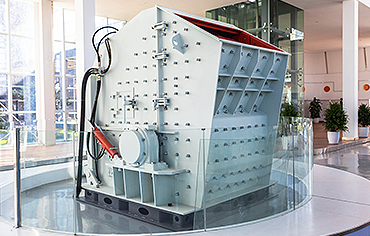

Autogenous and SAG Semi-Autogenous Mill Design

2018/4/17 The computer program can also be used to calculate power for larger or smaller volumetric loadings of balls. ... Current operational results show that the SAG mill is operating at 5% ball charge level by volume and is

获取价格

(PDF) Real-Time Estimation of SAG Mill Charge

2023/10/2 Control of the total charge and the ball charge volume is vital to the optimum performance of semi-autogenous grinding (SAG) mills to maximise throughput and energy efficiency.

获取价格

SAG mill ball charge determination and its influence on mill drive ...

In semi-autogenous grinding (SAG), the grinding mill inventory, (i.e. volume of total charge, volume of ball charge, etc.) is important in determining the optimum operating condition for

获取价格

SAG/Ball Mill - Bond - MetEngineer

SAG/Ball Mill Sizing Gross Power Draw and Specific Energy Calculator for Semi-Autogenous Grinding (SAG) and Ball Mills. Return to Mill Calculators. Shell Sizing Parameters.

获取价格

Real-Time Estimation of SAG Mill Charge Characteristics for

Control of the total charge and the ball charge volume is vital to the optimum performance of semi-autogenous grinding (SAG) mills to maximise throughput and energy efficiency.

获取价格

Modelling SAG milling power and specific energy consumption

2015/1/1 The ball charge is a function of the bulk fraction of the SAG mill volume (Jb) occupied by balls; the ore retained in the mill is the result of the volumetric filling which

获取价格

Modelling SAG milling power and specific energy

size, ball load, mill speed and % solids will represent the total load. Ball Mill SAG Mill Scw Jb Pc % -6" +1" N/Nc Fresh Feed Water Water Pebble Crusher Screen Cyclones Sump Pump Fig. 1.

获取价格

Model:Raw Bond/Barratt SAB SABC Model - SAGMILLING.COM

Ball-limited circuits (where the T 80 hits the lower limit) will result in the charge level in the SAG mill dropping until its power draw matches the throughput limit dictated by the ball mill. It is

获取价格

Real-Time Estimation of SAG Mill Charge Characteristics for

The charge mass is then estimated by subtracting the mass of the mill shell plus lifters and liners; but, the liner mass changes with wear and mill relines. However, when combined with an

获取价格

Mill Steel Charge Volume Calculation - 911Metallurgist

2015/6/19 We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media. While the mill is stopped,

获取价格

AG/SAG Mill Circuit Grinding Energy Requirement - How to

compared to those from the ball mill circuit. This has often resulted in conclusions concerning lower energy efficiencies of AG/SAG mill circuits compared to ball mills. The correlation between the AG/SAG and ball mill circuit data is also very poor. Use of equation 2 shows a very different picture, the results being illustrated in Figure 7.

获取价格

calculates the grinding charge of a ball mill

2013/3/8 METHOD FOR ESTIMATING THE BALL CHARGE OF A GRINDING MILL . a processor which is arranged to calculate a ball charge estimate using a Kalman filter which uses how to calculate sag mill ball charge ?

获取价格

Ball Mill Critical Speed - 911Metallurgist

2015/6/20 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula. The mill speed is typically defined as the percent of the

获取价格

Metallurgists Mineral Processing Engineers - 911Metallurgist

911 Metallurgist can enter the scene and see what you have become blind to. We can fix issues in ways you never thought possible. Our fresh eyes will open new opportunities for your plant. Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophy.The evaluation and prioritization of variables

获取价格

Circulating Load Calculation Formula - 911Metallurgist

2015/2/21 For example your ball mill is in closed circuit with a set of cyclones. The grinding mill receives crushed ore feed. The pulp densities around your cyclone are sampled and known over an 8-hour shift, allowing to calculate corresponding to circulating load ratios and circulating load tonnage on tons/day or tons/hour.

获取价格

Predicting SAG/AG Mill and HPGR Specific Energy

These can include both changes to how mills are operated eg ball load, speed etc but also changes to feed size distribution through modification to blasting practices and primary crusher operation – so-called Mine-to-Mill approach. 3.2 Mine-to-Mill The feed size to AG and SAG mill circuits has been demonstrated to have a significant impact

获取价格

Modelling SAG milling power and specific energy consumption including ...

2015/1/1 The ball charge is a function of the bulk fraction of the SAG mill volume (Jb) occupied by balls; the ore retained in the mill is the result of the volumetric filling which depends on the ore size distribution (specially the % +6″ and the % −6″ +1″), on the rotational speed (N/Nc) and on the solid concentration by weight fraction inside ...

获取价格

A Method to Determine the Ball Filling, in Miduk Copper

one SAG mill (9.75 dia.(m)*3.88 length(m)) following two parallel ball mills (5dia.(m)*7lenght(m)). The aim of this research work was to investigate on the ball filling estimation of Miduk semi-autogenous (SAG) Mill via an utilized method. Miduk SAG Mill circuit is shown in Figure 1. Figure 1: Diagram of Miduk Copper Complex SAG Mill Methods

获取价格

how to calculate sag mill ball charge – Grinding Mill China

Gulin Services, LLC. mill charge and speed.SAG Mill product P80 values are ) is then undertaken by back calculating and optimization of typically large SAG Mill/Ball Mills » Free Online Chat Mill (grinding) – Wikipedia, the free encyclopedia. To calculate the needed grinding work against the grain size changing The SAG mills use a minimal ball charge of 6 to 15%.

获取价格

Dynamic modeling and simulation of a SAG mill for mill

The modeling and simulation of semiautogenous (SAG) mills have been widely used in the design and optimization of mill performance in terms of its power draw, processing capacity and product size distribution. However, these models are solved under steady approximation and do not provide any information on mill charge distribution in real time.

获取价格

Grinding Mill Computer Model - AusIMM

Rowling are used to calculate the mill power draw. The Morgärdshammar equation and the IMM equations are shown for comparison. The method of use is similar to the AM section 3.3 Ball Mill Design The ball mill designs also follow the Bond/Rowlings method with comparison with other methods. Again the method of use is the same

获取价格

SAG Mill Grinding Circuit Design - 911Metallurgist

2016/6/6 Ball Charge Motion inside a SAG Mill. With a higher density mill charge. SAG mills have a higher installed power density for a given plant footprint relative to AC mills. With the combination of finer grind and a lower installed power density (based on the lower density of the mill charge), a typical AG mill has a lower throughput, a lower ...

获取价格

Ball Mill Design/Power Calculation - 911Metallurgist

2015/6/19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of

获取价格

SAG Mill Ball Size Evaluator Evaluation Factors Calculate

2013/9/8 Now, lets suppose you have a SAG Mill and Ball Mill that are not drawing full kW Power. The SAG 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise. SAG Mill Ball Size Evaluator Evaluation Factors Calculate ...

获取价格

Grinding Mill Computer Model - AusIMM

Rowling are used to calculate the mill power draw. The Morgärdshammar equation and the IMM equations are shown for comparison. The method of use is similar to the AM section 3.3 Ball Mill Design The ball mill designs also follow the Bond/Rowlings method with comparison with other methods. Again the method of use is the same

获取价格

SAG Mill Grinding Circuit Design - 911Metallurgist

2016/6/6 Ball Charge Motion inside a SAG Mill. With a higher density mill charge. SAG mills have a higher installed power density for a given plant footprint relative to AC mills. With the combination of finer grind and a lower installed

获取价格

Ball Mill Design/Power Calculation - 911Metallurgist

2015/6/19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill

获取价格

SAG Mill Ball Size Evaluator Evaluation Factors Calculate

2013/9/8 Now, lets suppose you have a SAG Mill and Ball Mill that are not drawing full kW Power. The SAG 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise. SAG Mill Ball Size Evaluator Evaluation Factors Calculate ...

获取价格

Design SAG mill production when you need it most: In day 1

Transfer Size, T80: Is the 80% passing size of ore as it passes from the SAG mill to the ball mill. It is typically about 1/3 the size of the screen opening but can be coarser than 1/3, especially when a pebble crusher is used. Screening at 5 mm ensures that the T80 will be about 10 mesh (1.7 mm) ensuring that the ball mill will work efficiently.

获取价格

MILLING CURVES AS A TOOL FOR CHARACTERISING SAG

Different to ball mills with constant fillings consisting mainly of balls, the fillings in SAG mills, consisting mainly of ore charge, can vary significantly during operation. The two main ...

获取价格

SAG Mill Liner Design - 911Metallurgist

2016/6/6 Mill manufacturers and experienced operators in this area have now learned to estimate the ball charge volume in a semi-autogenous charge using mill power draft and an average charge level as measured from mill centerline to top of charge. From a liner supplier standpoint, this method is certainly preferrable to grinding out.

获取价格

Grinding Media Wear Rate Calculation in Ball Mill

2017/4/29 The original ball load in the mill was 6614 lb. (3000 kg.) and the load at the end of the 694 hr. was 6338 lb. (2874.8 kg.). During this time, 590 lb. (267.6 kg.) of balls less than 3 in. (76.2 mm.) in diameter were discarded from the mill. The screen analysis of the ball charge at the end of the operation is shown in Table 20.

获取价格

Charge Motion inside a SAG Mill - 911Metallurgist

2018/6/24 Predicting the composition of the SAG mill charge is a difficult task since a number of significant phenomena associated with the charge motion must be taken into consideration. ... For most steady-state conditions examined there is no creation of a water pool (which is typical of overflow mills) at the toe of the ball charge.

获取价格

Calculate Ball Mill Grinding Capacity - 911Metallurgist

2015/10/15 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge

获取价格

Ball Mill Design Calculations How To PDF

The document provides information on how to calculate ball mill design and sizing parameters. It includes a small ball mill capacity and sizing table, as well as details on ball mill design and power calculations. The document advertises various metallurgical testing, engineering, and plant troubleshooting services available through 911Metallurgist.

获取价格

Inferential measurement of SAG mill parameters III: inferential models

2002/12/1 Similar to the powerdraw model utilisation, mill weight models have been utilised to measure the total charge level (J t) given the ball charge level (J b), or, used in conjunction with mill powerdraw models in state estimation contexts to estimate both the total and ball charge levels (Herbst and Pate, 1999; Apelt et al., 2001b).Apelt et al. (2001b) present the novel use of

获取价格

Understanding the effects of liner wear on SAG mill performance

2015/9/7 For example, liner wear can greatly affect SAG mill performance (Toor et al., 2015) and simply including the entire historical dataset might not be optimised to predict SAG mill performance. This ...

获取价格