أرسل لنا رسالة

function of screening plant in iron ore

The impact of new technologies on the iron ore screening flowsheet

2024/1/16 The paper offers insights into significantly improving the screening efficiency

获取价格

Impact of key parameters on the iron ore pellets roller

studies related to this important equipment. It is a review manuscript describing the screen variables and its impact on the iron ore pelletizing process. Keywords: roller screening performance / roller screen / roller feeder / iron ore pellets quality / plant productivity 1 Introduction The iron ore pellet is one of the most important raw

获取价格

Comminution and classification technologies of iron ore

2022/1/1 Some examples of different iron ore crushing and screening flowsheets are provided below: 8.2.3.1. Rio Tinto iron ore processing plants. Rio Tinto Iron ore processing plants in the Pilbara region of Western Australia do not involve any chemical treatment. ... Blending of the three ores is an important function performed by the coarse ore ...

获取价格

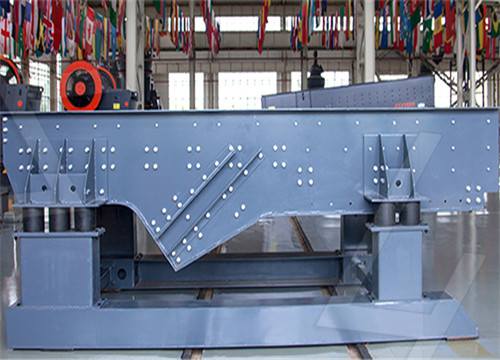

(PDF) ORE SEPARATION BY SCREENING - ResearchGate

2017/3/3 For example, one of such objects in minerals processing plants is the vibrating screen, Fig. 1. Sieving is a process of separation of the ore material into multiple grades by particle size [1] .

获取价格

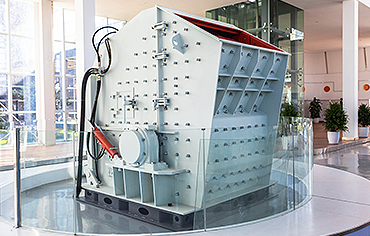

Crushing Screening Plant - 911Metallurgist

2016/7/12 Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers.. Crushing is done underground at a few large mines. In general, the jaw crusher is the most suitable primary machine, yet many gyratories do the

获取价格

Mobile Crushing and Screening Plant Applications for Small

There is now a new generation of mobile crushing and screening plant systems available which have been developed based on the motivation of reducing truck haulage. Newly designed mobile crushing and screening plant systems have the advantages of mobility, flexibility, economy and reliable performance, making this system very appealing for small- to medium-sized projects

获取价格

The impact of new technologies on the iron ore screening

the screening efficiency of iron ore pelletizing plants by comparing the performance of the operational unit using a standard screening flowsheet versus the proposed one. 2 Experimental Simulations using the discrete element method (DEM) were conducted using an open-source code from woodem. org. The roller screen module was developed by Woodem

获取价格

Transforming iron ore processing – Simplifying the comminution

2023/8/1 Much of the remaining iron ore resources in Brazil consist of low-grade itabirite ores. Accordingly, a typical beneficiation circuit includes a four-staged crushing/screening plant, followed by grinding in a closed-circuit ball mill, desliming in hydrocyclones and final ore mineral concentration via multistage reverse flotation and thickening of the final product.

获取价格

The impact of new technologies on the iron ore screening

2024/1/16 The paper offers insights into significantly improving the screening efficiency of iron ore pelletizing plants by comparing the performance of the operational unit using a standard screening flowsheet versus the proposed one. 2 Experimental. Simulations using the discrete element method (DEM) were conducted using an open-source code from woodem ...

获取价格

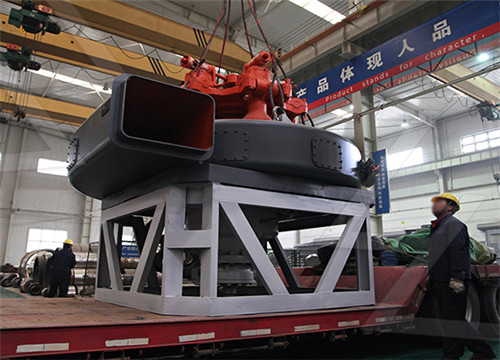

Mobile screening plants in a large-scale operation in India PM

The red colour usually allows you to spot it from a distance: iron ore. The volcanic rock is mainly used in the manufacture of steel. India has vast reserves of iron ore and is the second biggest steel producer in the world. The mobile screening plants MOBISCREEN EVO from are used during the extraction of the important material.

获取价格

sbm/sbm function of screening plant in iron ore.md at master

sbm function of screening plant in iron oreflowsheet assessment and capacity evaluation of an iron ore. Original scientific paper.An iron ore processing plant in Sivas (Turkey) was investigated and simulated depending on real and experimental data in this study.The AggFlow™ simulation packaged program was used and the experimental results conducted in mineral processing

获取价格

Sintering plant at a glance PPT - SlideShare

2014/10/27 5. 5 Material flow Diagram Sintering Plant Flux Hammer Crusher Flux Screen +3mm Stock Bin proportioning section Iron Ore Fines -3mm Coke breeze from C O PMD Hot Sinter return -5mm Cold Sinter return Cold Sinter return Coke return from B F -25mm -3mm Fuel Storage Coke crusher Sinter M/c Hot screen SLC Cold screen Sinter to BF -8mm -5mm Waste

获取价格

pRE-feasibility report of SCREENING CUM BENEFICIATION

PRE-FEASIBILITY REPORT OF SCREENING CUM BENEFICIATION PLANT OF BAILADILA IRON ORE DEPOSIT-4 S.no. Particulars Capacity 1 Activity Processing of 7 MTPA of crushed iron ore in Screening cum Beneficiation plant to get final products such as Calibrated Lump Ore and Fine Ore. Slime generation during wet screening operations.

获取价格

(PDF) Overview of ArcelorMittal Mining Operations and Research ...

2016/6/23 The iron ore of the Ljubija ore region for decades has a very great impact on the overall social reproduction in the area of the city of Prijedor, RS, BiH, which is clearly connected with the ...

获取价格

Beneficiation of Fine Iron Ores using the Desand Process - AusIMM

The low-grade clay-rich -1.0 mm fraction of fine iron ores have often proved difficult to upgrade and capital intensive to process when using traditional wet beneficiation technology including single or two stage hydrocyclone desliming, wet high intensity magnetic separation (WHIMS), spirals and final dewatering using fine screens. Very fine (<0.010 mm) clay-rich slimes simply

获取价格

Sintering plant at a glance PPT - SlideShare

2014/10/27 5. 5 Material flow Diagram Sintering Plant Flux Hammer Crusher Flux Screen +3mm Stock Bin proportioning section Iron Ore Fines -3mm Coke breeze from C O PMD Hot Sinter return -5mm Cold Sinter return

获取价格

pRE-feasibility report of SCREENING CUM BENEFICIATION

PRE-FEASIBILITY REPORT OF SCREENING CUM BENEFICIATION PLANT OF BAILADILA IRON ORE DEPOSIT-4 S.no. Particulars Capacity 1 Activity Processing of 7 MTPA of crushed iron ore in Screening cum Beneficiation plant to get final products such as Calibrated Lump Ore and Fine Ore. Slime generation during wet screening operations.

获取价格

(PDF) Overview of ArcelorMittal Mining Operations

2016/6/23 The iron ore of the Ljubija ore region for decades has a very great impact on the overall social reproduction in the area of the city of Prijedor, RS, BiH, which is clearly connected with the ...

获取价格

Beneficiation of Fine Iron Ores using the Desand Process - AusIMM

The low-grade clay-rich -1.0 mm fraction of fine iron ores have often proved difficult to upgrade and capital intensive to process when using traditional wet beneficiation technology including single or two stage hydrocyclone desliming, wet high intensity magnetic separation (WHIMS), spirals and final dewatering using fine screens. Very fine (<0.010 mm) clay-rich slimes simply

获取价格

Function Of Screening Plant In Iron Ore - cnttravel.co

Screening Plant Iron Ore . Function of screening plant in iron ore Grinding Mill The Gulin product line consisting of more than 30 machines sets the standard for our industry We plan to help you meet your needs with our equipment with our Live Chat; Mobile Crushing and

获取价格

Iron Ore Screening - Multotec

Iron ore screening equipment from Multotec is made from polyurethane or rubber screening media.Our screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirements. Our polyurethane and rubber iron ore screening solutions are

获取价格

Introduction to Iron ore Pellets and Pelletizing processes

2013/2/23 The various advantages of iron ore pellets are given below. Iron ore pellet is a kind of agglomerated fines which has better tumbling index when compared with the iron ore and it can be used as a substitute for the iron ore lumps both in the BF and for DRI production. Pellets have good reducibility since they have high porosity (25 % to 30 %).

获取价格

Ore, Rock Aggregate Screening (Complete Guide)

2016/6/20 Effect on screening of the particle distribution of the feed. The particle distribution of the feed has an essential impact on purity. See three examples in figure 1. In each one of them the efficiency is 90 %, but the undersize proportion of the coarse fraction varies (3.2 %, 9.1 %, 23 %). Effect on screening of the chosen screen hole size

获取价格

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing.

获取价格

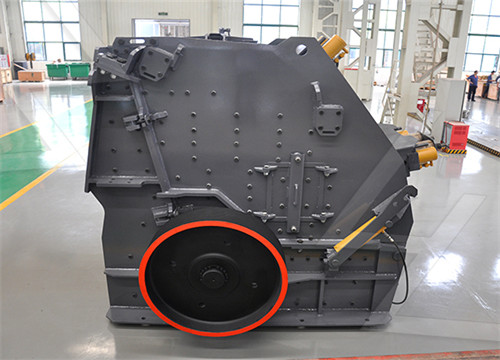

The impact of new technologies on the iron ore screening

2024/4/19 The iron ore screening process plays a pivotal role in determining the dimensions of pellets that enter the firing process of a pelletizing plant.

获取价格

INTEGRATION OF IRON ORE DEPOSIT EVALUATION AND

Joda East Iron Mine (JEIM) is one of the major captive sources of iron ore to the Tata Steel plant at Jamshedpur and supplies approximately 45% of work’s total iron ore requirement. The mine produces iron ore fines (0.15–10 mm) and sized ore (10–40 mm). The iron ore, which belongs to

获取价格

Iron Ore Processing Equipment - Haver Boecker Niagara

Iron Ore Screening Plant. Niagara vibrating screens support iron ore producer to screen more than 90 million tons of iron ore annually. ... The vibrating screen has the function to dewater the material from wet high-intensity magnetic concentration and wet medium-intensity magnetic concentration underflow. The dewatering screen has a feed ...

获取价格

screening plants for iron ore mining in Odisha

mobile screening plants . Six mobile screening plants are deployed on the Keonjhar site, since January 2020 to systematically screen the final output of the required sizes. Five of the mobile screens are of double deck configuration (MS 952 EVO) with three outputs and one screen is of triple deck (MS 953 EVO) with four outputs.

获取价格

Mobile Screening Station-Multi-Functions, High Mobility - Fote

Mobile Screening Plant. Applications: it is used to crush river gravel, limestone, granite, basalt, andesite, iron ore, quartz, diabase, iron ore, gold ore, copper ore in the industries of mining, coal, garbage and construction waste recycling, earthwork, urban infrastructure, roads or construction sites and others.

获取价格