أرسل لنا رسالة

Mineral powder grinding Process

Grinding: A Comprehensive Guide to Particle Size Reduction and

Tuxingsun Mineral Mining provides an in-depth overview of grinding, a fundamental process in

获取价格

Grinding powder production line: Process configuration and flow

The choice of grinding equipment depends on the material properties and the desired fineness

获取价格

MINERAL PROCESSING - MILLING - United Diversity

MINERAL PROCESSING - MILLING Introduction Milling, sometimes also known as fine

获取价格

Essential Guide to Mineral Processing Equipment - Flyability

Mineral Processing Plants: What You Need to Know

2024/8/15 Comminution involves both crushing and grinding. As the first step in mineral processing, comminution is to process large pieces of ore into smaller pieces with the help of crushers and grinders. 2. Sizing/Screening

获取价格

Mineral Processing: An In-Depth Guide - JXSC

2024/2/23 The grinding process helps separate the good minerals from the useless parts and makes sure the next steps, like separating the minerals, work even better. Step 2: Screening and Classifying After we pulverize and crush

获取价格

Mineral Prossesing - KIIT Polytechnic

Process Feed Size Product size 1. Coarse Crushing ROM( 150-4cms) 5.0- 0.5 cm 2.

获取价格

Powder Milling and Grinding - An Engineering Guide

Milling / Grinding / Comminution / Size reduction Milling Process Technologies A free online

获取价格

The role of mineral powder grinding mills in industrial production

Modern mineral powder grinding mills are designed to be energy-efficient. The use of

获取价格

Mineral ultrafine grinding equipment EPIC powder

Mineral powder grinding machinery is a type of equipment used to grind various minerals into fine powder. Skip to content. Email: [email protected] Tel: +86 15762272120; ... low noise in a clean and environmentally friendly process. It can realize the functions of drying, dispersing and modification at the same time. According to material ...

获取价格

Guide - [Updated] Efficient Powder Grinding Hypixel

2024/9/23 Powder Hoarder Perk: Gives +6% more powder during Mining Fiesta. Further Tips: Always farm powder during a 2x Powder Event, as it doubles your overall powder gains. Even if the 2x Powder Event ends in your current

获取价格

Copper Ore Production Process - JXSC Mineral

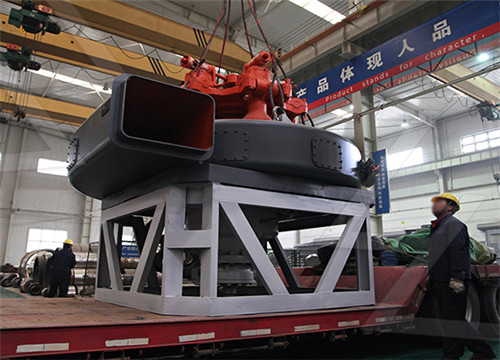

2023/5/6 In the crushing process of copper ore processing, the two-stage-closed-circuit crushing-single-stage ball milling process is more common in small copper ore concentrators whose production scale is below 500t/d. Three

获取价格

Powder Milling and Grinding - An Engineering Guide

Solids Milling Engineering Guide Milling / Grinding / Comminution / Size reduction Milling Process Technologies A free online Engineering Guide to the powder granulates milling technologies and principles.

获取价格

Cobalt Mining Process - JXSC Mineral

After grinding, the qualified cobalt ore powder is sent to the ... We do not buy or sell mineral ores. We provide ore process design, mining equipment production, and solutions. China Mining Equipment Manufacturer. Contact Tel: +86-13879771862 ...

获取价格

Raymond Mill - JXSC Machinery

We support providing complete powder grinding plant equipment, including cyclone powder collector, dust collector, bucket elevator, ... We only provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials. ... Chrome Washing Process; Contact Us +86-18879767229 [email protected] Factory Address: No.16, Gongye ...

获取价格

Intelligent process control system for predicting operating

2024/1/31 Mineral Processing and Extractive Metallurgy: Transactions of the Institutions of Mining and Metallurgy ... Woywadt C. Grinding process optimization – featuring case studies and operating results of the modular vertical roller mill. ... Wang K, Li X, Jia C, et al. Tracking control of slag powder production process based on adaptive dynamic ...

获取价格

Thermodynamic analysis of mineral powder grinding processes

2024/3/11 The main theoretical prerequisites for the thermodynamic analysis of the process of grinding rocks are given. The structural-energetic relationships between the regularities of plastic deformation with energy characteristics that occur during the crushing of mineral substances are described.

获取价格

Energy Use of Fine Grinding in Mineral Processing

2013/12/18 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor. While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s energy budget. Overall

获取价格

Trusted Industrial mineral powders manufacturer in India

Natural Minerals stands at the forefront of industrial mineral powder suppliers in India, renowned for its commitment to excellence. As a leading manufacturer, we pride ourselves on our state-of-the-art manufacturing facilities and highly skilled team, delivering a diverse range of premium-quality minerals.

获取价格

The role of mineral powder grinding mills in industrial production

The vertical arrangement of the grinding mechanism reduces the space required and improves the efficiency of the grinding process. 3. Raymond Mill ... Mineral powder grinding mills are indispensable in the mineral processing industry, providing the necessary fine powders for a wide range of applications. With advancements in technology, these ...

获取价格

Grinding - Hosokawa Alpine

The material to be ground is subjected to compressive stress between the grinding table and the grinding rollers, and is comminuted in the process. They are suitable for brittle/elastic grinding materials; the fineness level of the end product is between 20 µm and 100 µm. Popular applications include soft to medium-hard mineral raw materials.

获取价格

Four Common Types Of Fluorspar Mineral Processing Methods

6 之 The process begins by crushing and grinding the ore into a fine powder, which is then mixed with water and collector chemicals. The mixture is then aerated, causing the quartz particles to float to the surface and the fluorspar to sink, allowing for easy separation. Another is the need for selective flotation agents specific to each mineral.

获取价格

The role of mineral powder grinding mills in industrial production

The vertical arrangement of the grinding mechanism reduces the space required and improves the efficiency of the grinding process. 3. Raymond Mill ... Mineral powder grinding mills are indispensable in the mineral processing industry, providing the necessary fine powders for a wide range of applications. With advancements in technology, these ...

获取价格

Grinding - Hosokawa Alpine

The material to be ground is subjected to compressive stress between the grinding table and the grinding rollers, and is comminuted in the process. They are suitable for brittle/elastic grinding materials; the fineness level of the end

获取价格

Four Common Types Of Fluorspar Mineral Processing

6 之 The process begins by crushing and grinding the ore into a fine powder, which is then mixed with water and collector chemicals. The mixture is then aerated, causing the quartz particles to float to the surface and the

获取价格

A comprehensive review on the grinding process: Advancements ...

2022/6/24 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and automobiles.

获取价格

Sepiolite Superfine Powder Grinding Mill - SBM Ultrafine Powder

2021/9/29 Sepiolite crushing and grinding process: Sepiolite powder is the main raw material of sepiolite mud, which is a kind of hydrated magnesium silicate clay mineral that is purely natural, non-toxic, tasteless, non-asbestos, and non-radioactive elements. ... Phosphate mineral powder grinding mills includes ultrafine mills, vertical roller mills ...

获取价格

Ultra-fine grinding mill: Revolutionizing the mineral powder

Improved Process Control. The advanced control systems of ultra-fine grinding mills allow for better process control, enabling operators to fine-tune production parameters for optimal results. The ultra-fine grinding mill has emerged as a powerful tool in

获取价格

Industrial mineral powder production in China - ScienceDirect

2007/12/1 Use of combined dry/wet process and compound modification systems, including ultra-fine grinding with surface modification, consecutive drying with surface modification, inorganic precipitation coating with organic surface modification, and mechano-chemical processing with organic coating modification. 3.4.

获取价格

A Review of the Grinding Media in Ball Mills for Mineral

2023/10/27 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as

获取价格

Grinding: A Comprehensive Guide to Particle Size Reduction and Powder

Tuxingsun Mineral Mining provides an in-depth overview of grinding, a fundamental process in mineral processing, powder processing, and various industrial applications. Explore the principles and techniques involved in particle size reduction, encompassing ball mills, rod mills, hammer mills, and attrition mills. Delve into the selection of grinding media, including steel balls, rods,

获取价格

Mineral ultrafine grinding equipment EPIC powder

2024/7/28 Mineral powder grinding machinery is a type of equipment used to grind various minerals into fine powder. ... low noise in a clean and environmentally friendly process. It can realize the functions of drying, dispersing and modification at the same time. According to material hardness, added value, output, etc., choose a better solution.

获取价格

Comminution a Heart of Mineral Processing - ResearchGate

2021/7/6 dimension, and ends with grinding the reduced materials into powder. Be it mine-to-mill reduction or crushing and grinding of ore particles, comminution improves the surface area of

获取价格

Mineral Coarse Powder Grinding Mill- HAMAC - hamacmix

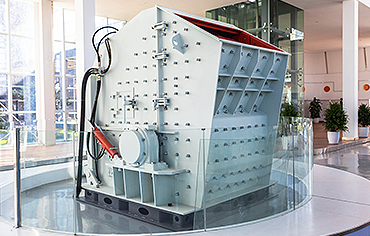

The Mineral Coarse Powder Grinding Mill is a high-efficiency grinding machine specifically designed for the processing of various minerals. This innovative mill features a robust construction that ensures durability and longevity in demanding environments. Equipped with advanced technology, it effectively reduces large mineral particles to a fine powder, making it ideal for

获取价格

Marble Ultrafine Powder Grinding Mill - SBM Ultrafine Powder

2021/9/6 Marble crushing and grinding process: Marble crushed stone and leftover material are processed by an industrial powder mill machine, and marble powder of different fineness can be obtained. ... Phosphate mineral powder grinding mills includes ultrafine mills, vertical roller mills, high-pressure mills, etc. can grind ores into a fine powder ...

获取价格