أرسل لنا رسالة

Coarse Material Roller Mills

Raymond® Roller Mills - Coperion

The mill provides efficient control of product size with minimal power, resulting in a flexible, cost-effective production. Standard size. Raymond® Roller Mills are available with grinding ring diameters ranging from 30-120 in/ 760-3050mm.

获取价格

Polysius Roller Mills. For grinding

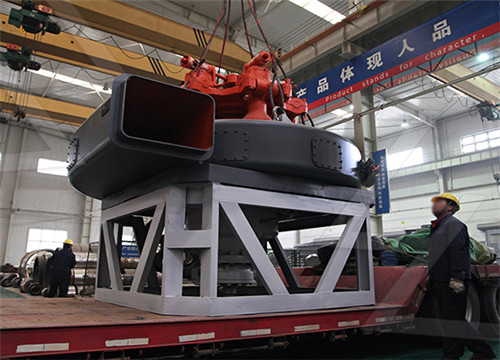

material feed system of a roller mill. Stages in the assembly of a roller mill in Australia. View

获取价格

Vertical Roller Mills: Technology, Equipment, Advantages

2024/9/25 Main flow across Vertical Mills Materials flows: the table rejects This is the rejects material of the mill. It comes out of the rejects chamber and get fed back to the mill via the fresh feed. This is called the EXTERNAL circulating load The flow of this material is always measured to calculate the total feed to the mill On these type of mills the aim is to handle an

获取价格

Exploring the Different Types of Roller Mills

5 之 Horizontal roller mills are often compared with vertical roller mills, and they boast several advantages: Better particle size distribution: The horizontal arrangement can lead to a more consistent grind. Lower initial investments: Sometimes they are more economical when it comes to capital expenditure. Flexible operation: Skilled operators can adjust horizontal mills

获取价格

Polysius Roller Mills. For grinding

Roller mill for cement raw material grinding in China. Roller mill for cement clinker grinding in Mexico. Coal grinding plant in Poland. 4 Advantages of Polysius roller mills ... for coarse material and an inlet chute designed to suit the mill feed material are integral parts of the grinding system. Both the coarse feed valve and the chute

获取价格

Vertical Roller Mills used for the comminution of mineral ores

Vertical roller mill (VRM) is an established technology in cement and slag grinding applications and Boliden ... The material to be ground is fed into the centre of the ... the table overflow upwards to the classifier where finished product continues upwards and out of the mill while coarse particles flow downwards and are returned to the mill ...

获取价格

Using the eight-roller mill in the purifier-less mill flow

2014/12/20 After each grinding stage a mixture of coarse, medium and fine fractions (including flour) is sieved and the undersize material is removed before regrinding. The roller mills are the primary grinders in the flour mill ... The eight-roller mill (8 rolls in one housing), also known as two high or double high roller mill, provides two grinding ...

获取价格

Roller Screens - BEUMER Group

Loamy, sticky adhesions to the coarse material are separated and screened together with the end product. ... especially in case of hard to screen raw materials (coarse, moist, clumpy, sticky, etc.). Our roller screens are primarily deployed in coal fired power plants for pre-screening and crusher relief, as well as for separation or control ...

获取价格

Vertical raw mill pradeep kumar PPT - SlideShare

2013/5/15 The coarse material coming from the separator is directed back to the centre of the grinding plate in order to be ground again. The grinding process starts with the preparation of the so- called grinding bed, where the coarse material is crushed. ... leading to the vertical roller mill on the thin material, and even disc direct contact with the ...

获取价格

Roller mill - Lessine

For primary, coarse or medium milling, the roller mill crushes and/or tears the material while keeping strict distribution of particles.

获取价格

quadropol® - Vertical Roller Mill - myPolysiusService

For raw material grinding a quadropol® vertical roller mills QMR² 45/23 was contracted to serve the kiln line, while for cement grinding two identical QMC² 45/23 were considered for grinding different cement types. The request for interchangeable parts for the three mills was fulfilled and represents still a holistic approach.

获取价格

AIRSWEPT PENDULUM MILL SYSTEM - Bradley Pulverizer

Our flagship pendulum roller mills are equipped with three ... assemblies to swing outward against the stationary ring. Plows direct material from the mill floor to the grinding zone where it is ground using a combination of attrition and impact. ... COARSE REJECT BACK TO MILL. AIRSWEPT PENDULUM MILL SYSTEM RECYCLED vs. SINGLE PASS AIR SYSTEM

获取价格

Analysis of vertical roller mill performance with changes in material ...

2022/5/31 The vertical roller mill (VRM), including powder separation and crushing sub-systems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical. ... There is about 35% of the medium size in the products (1.25–3 mm), with about 51.6% of coarse material in the products (>3 mm ...

获取价格

Best HLM Vertical Roller Mill Manufacturer and Factory

HLM Vertical Roller Mill For Coarse Cement. Model: Grinding table median diameter (mm) Capacity (t/h) Product Moisture: Fineness: Power (kw) HLM30/2: 2500: 85-100 <10%: R0.008<12%. 800/900: HLM34/3: 2800: ... The hot air will dry the floating material and blow the coarse material back to the dial. The fine powder will be brought to the ...

获取价格

quadropol® - Vertical Roller Mill - myPolysiusService

For raw material grinding a quadropol® vertical roller mills QMR² 45/23 was contracted to serve the kiln line, while for cement grinding two identical QMC² 45/23 were considered for grinding different cement types. The request for

获取价格

AIRSWEPT PENDULUM MILL SYSTEM - Bradley Pulverizer

Our flagship pendulum roller mills are equipped with three ... assemblies to swing outward against the stationary ring. Plows direct material from the mill floor to the grinding zone where it is ground using a combination of attrition and impact. ... COARSE REJECT BACK TO MILL. AIRSWEPT PENDULUM MILL SYSTEM RECYCLED vs. SINGLE PASS AIR SYSTEM

获取价格

Analysis of vertical roller mill performance with changes in material ...

2022/5/31 The vertical roller mill (VRM), including powder separation and crushing sub-systems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical. ... There is about 35% of the medium size in the products (1.25–3 mm), with about 51.6% of coarse material in the products (>3 mm ...

获取价格

Best HLM Vertical Roller Mill Manufacturer and Factory

HLM Vertical Roller Mill For Coarse Cement. Model: Grinding table median diameter (mm) Capacity (t/h) Product Moisture: Fineness: Power (kw) HLM30/2: 2500: 85-100 <10%: R0.008<12%. 800/900: HLM34/3: 2800: ... The hot air will dry the floating material and blow the coarse material back to the dial. The fine powder will be brought to the ...

获取价格

Size Reduction – Visual Encyclopedia of Chemical Engineering

A popular type of vertical spindle mill is the ring-roller mill. General Information. In ring-roller mills rollers feed solid coarse particles against a stationary grinding ring. The particles are broken apart by the resulting compression forces. Equipment Design. In a ring-roller mill, the material to be milled is fed into the grinding section.

获取价格

Coarse Powder Grinding Mill - SBM Ultrafine Powder Technology

Carbon black is a light, loose and fine black powder that contains carbon substances. It can be used as a black dye to make ink, paint, rubber material, etc. Carbon black ultrafine mill is also called (three-ring four-ring) medium-speed ring roller micro-grinding machine. It adopts a graded continuous grinding method to grind the material ...

获取价格

Using the eight-roller mill in the purifier-less mill flow - PMC

After each grinding stage a mixture of coarse, medium and fine fractions (including flour) is sieved and the undersize material is removed before regrinding. The roller mills are the primary grinders in the flour mill ... The eight-roller mill (8 rolls in one housing), also known as two high or double high roller mill, provides two grinding ...

获取价格

Coarse Material Washers - Eagle Iron Works

By adding more paddles to the shaft(s), each Coarse Material Washer can be configured to meet the different specific scrubbing needs of various materials. Additional paddles, while slightly reducing capacity, allow material to be retained in the Coarse Material Washer’s tub area, providing additional scrubbing.

获取价格

Roller mill - Wikipedia

Roller mills are mills that use cylindrical rollers, ... in which the material is crushed between two rollers before it continues on to its final destination. ... husk without much damage to the husk, but leaves large grits. Flour is sieved out of the cracked grain, and then the coarse grist and husks are sent through the second set of rollers ...

获取价格

Review on vertical roller mill in cement industry its

2021/1/1 Big feed size - The vertical roller mill can grind the material of particle size of 5% of the grinding roller diameter. The feed size is generally 40 to 100 mm and can reach 120 mm in case of large VRM. ... Coarse material fall onto the feed table for further size reduction, whereas fine material passes through rotating classifier with ...

获取价格

Coarse Feed Valve - myPolysiusService

Coarse feed valves serve as airlocks and as continuous feeding units for coarse-grained materials. ... This type of feed valve is primarily used upstream of roller mills and ball mills for supplying coarse-grained bulk materials such as limestone and coal with a particle size range of 0–200 mm, depending on the size of feed valve involved ...

获取价格

Roller Mill - Calcium Carbonate Production Line

2024/6/7 The ring roller mill uses the principles of impact, extrusion and grinding to crush materials. There are multiple layers of grinding rollers and grinding rings installed, and the material first falls between the uppermost grinding rollers and grinding rings. ... and the coarse material is thrown to the inner wall of the diversion ring, and ...

获取价格

Raymond® Roller Mills - Coperion

The Raymond® Roller Mill is an air-swept vertical ring-roll mill withan integral classification system that simultaneously dries, ... the roller mill can produce particles ranging from coarse, granular products of approximately 10% R2000 micron90% minus 10 mesh (10%R2000 microns) to as fine as 99.9% minus 325 mesh (0.001%R44 micron ...

获取价格

Raymond Roller Mills Vs. Williams Roller Mills Midwest

2024/10/16 Both Raymond and Williams Roller Mills have established themselves as trusted solutions in industries like mineral processing and manufacturing, but which one is best for your needs? In this guide, we’ll compare their features, applications, and benefits to help you make an informed decision.

获取价格